Your Partner for Advanced Metal Manufacturing and Materials

High-Quality Titanium & Titanium Alloy Materials

OEM and ODM are accepted

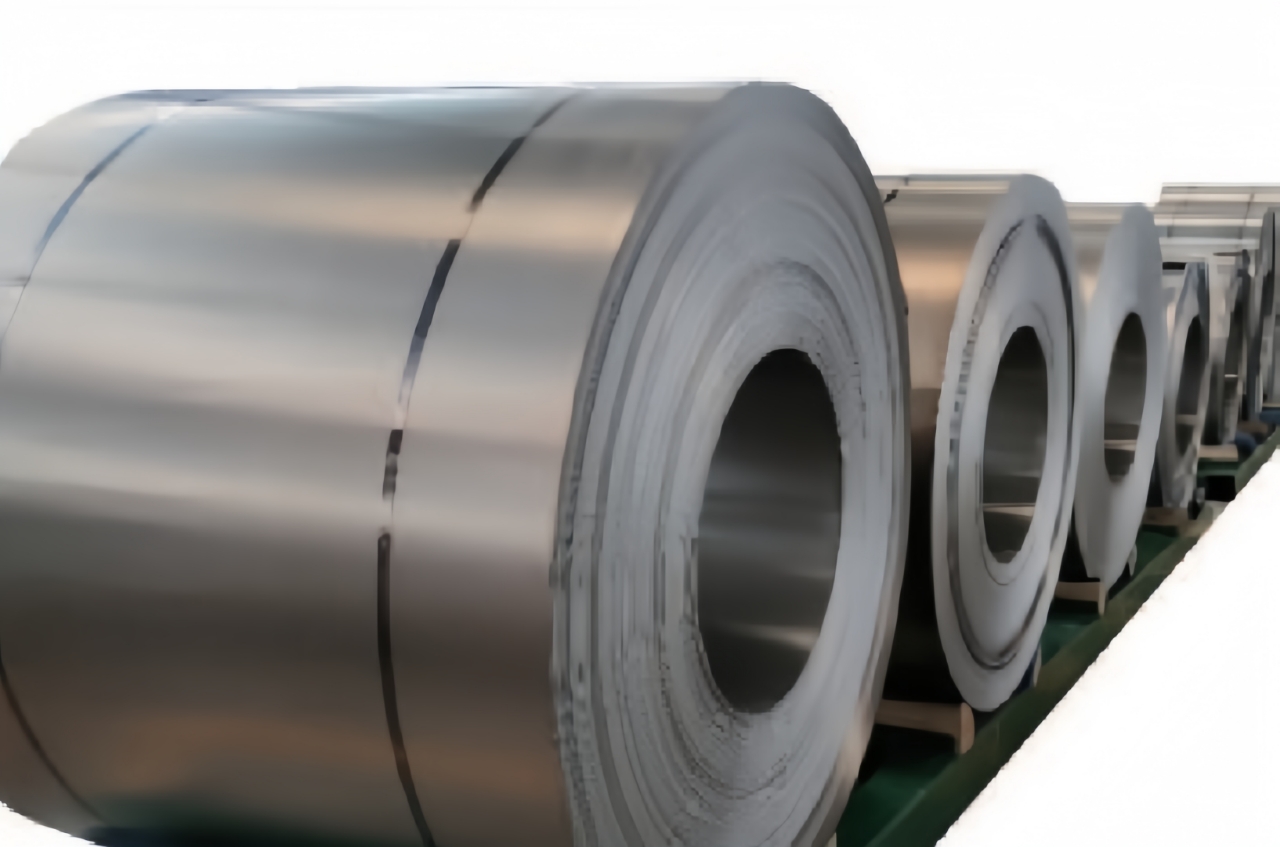

Cold &Hot Rolling Coil

TA1(Gr.1),

TA2(Gr.2), TA3(Gr.3),

TA4(Gr.4),

TA8, TA9,

TA10(Gr.12),

TC4ELI(Gr.23) etc.

Sheet&Plate

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA4(Gr.4), TA5,TA7(Gr.6), TA8, TA9(Gr.7),TA10(Gr.12), TA15(BT20), TC1,TC2, TC4(Gr.5), TC6, TC11, TC18,TB2,TB5,TB6,T165,

T160,R60700,R60702

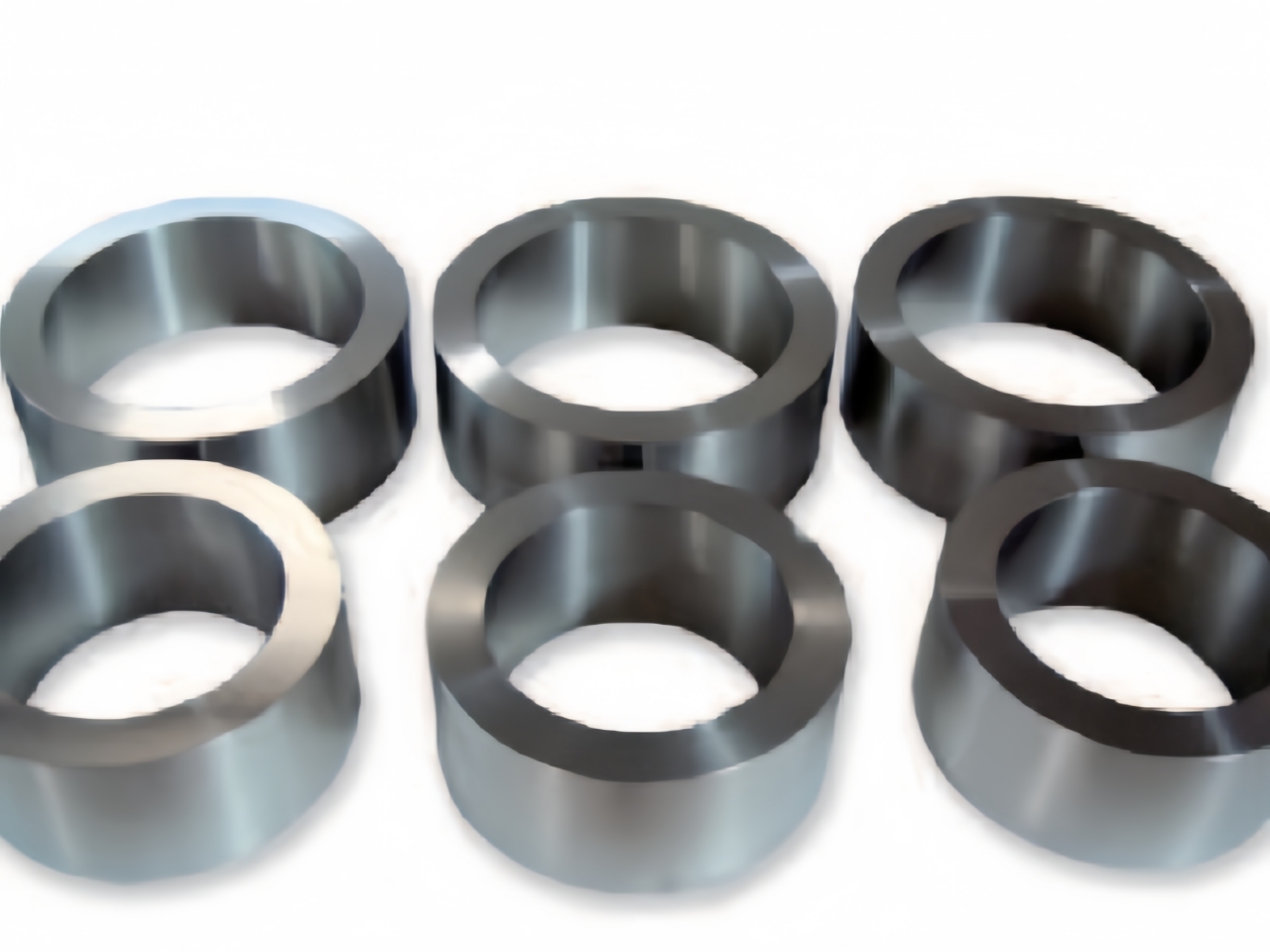

Forging

TA1(Gr.1 ), TA2(Gr.2),TA3(Gr.3),TA4(Gr.4),TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11, TC17,TC18(BT22), C.P.Ti, Gr.11,Gr.17,TI-6AI-4VELI, TC10(Ti662),TA19(Ti6242),TC19(Ti6246),TC21(-Ti62222s),TB2,TB5,TB6(Ti1023)

Billet Bar& Rod

TA1(Gr.1 ), TA2(Gr.2), TA3(Gr.3), TA4(Gr.4)TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11,TC17,TC18(BT22),C.P.Ti, Gr.11,Gr.17,Ti-6A1-4VELI, TC10(Ti662),TA19(-Ti6242),TC19(Ti6246),TC21(Ti62222s),TB2, TB5, TB6(Ti1023)

Wire

TA1(Gr.1), TA2(Gr.2),

TA3(Gr.3),TA10(Gr.12),

TA15(BT20),TA18(Gr.9),

TC4(Gr.5),C.P.Ti, Gr.11,

Gr.17,Ti-6AI-4VELI,

TC16,TB3,TB8,TB13 etc.

Leading the Way in Materials Production

We are a company that integrates research and development with production.

We possess first-class domestic and internationally advanced titanium and titanium alloy production facilities,

testing technologies, and a team of top-tier professionals.

Titanium Strip&Clad Coil System

We specialize in the production of various specifications of hot-rolled and cold-rolled titanium coils, including TA1 (Gr.1), TA2 (Gr.2), TA3 (Gr.3), TA4 (Gr.4), and TA10 (Gr.12). Additionally, we offer titanium/aluminum/steel, titanium/aluminum/titanium, and titanium composite plates and strips, as well as titanium composite round discs.

Sheet&Plate Product System

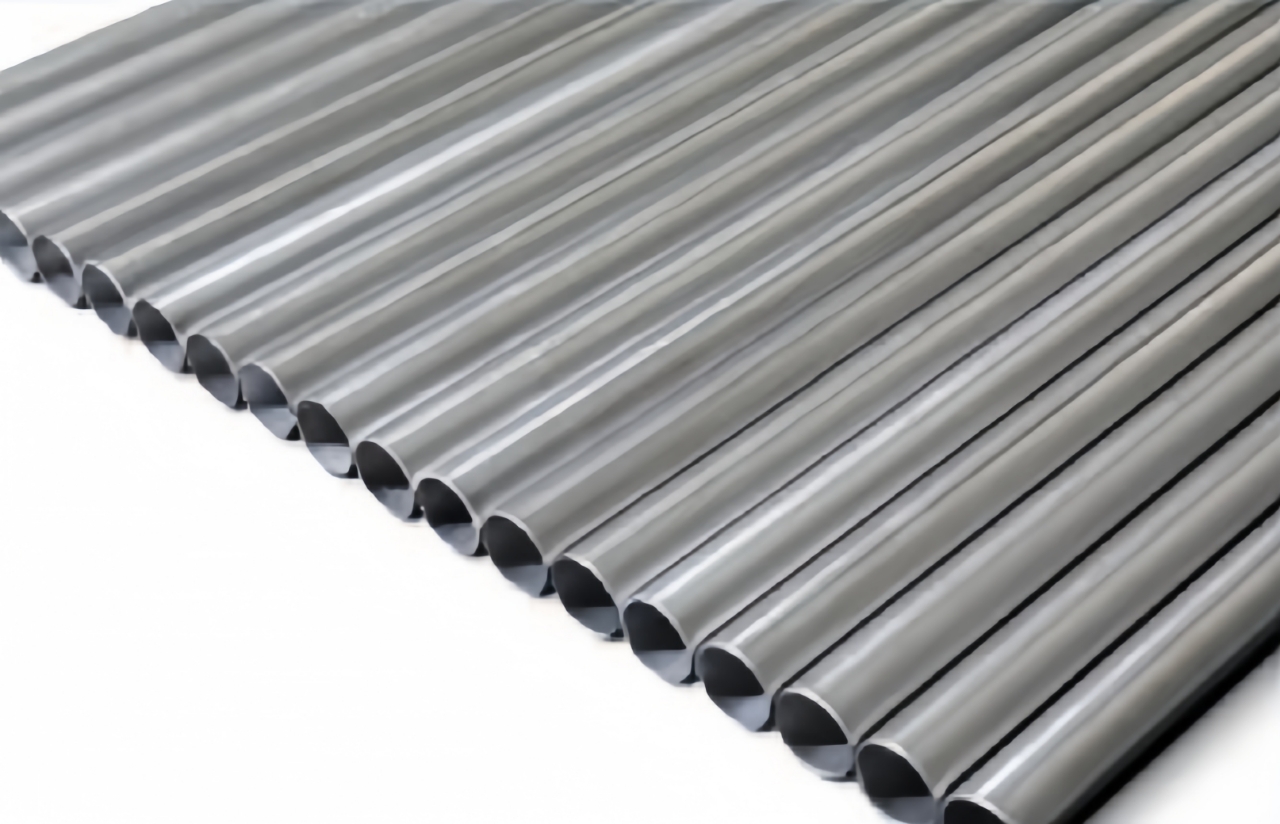

The plate production line is equipped with a complete set of systems and equipment for producing thin and medium-thick plates of rare metals such as titanium and titanium alloys, zirconium and zirconium alloys, as well as some high-temperature alloy plates. The main equipment includes heating and heat treatment units, a 2450mm four-roll reversible hot rolling mill, leveling equipment, surface treatment equipment, finishing equipment, flaw detection systems, and other auxiliary devices.

The 2450mm four-roll reversible hot rolling mill was designed and manufactured in collaboration with a leading domestic metallurgical equipment manufacturer, taking into account the unique characteristics of titanium and titanium alloy processing, and is paired with an advanced automatic control system. The equipment selection and process layout of the hot rolling line are more suitable for the production process requirements of titanium alloy medium-thick plates.

By incorporating a vacuum creep leveling furnace and an Italian-imported thin plate sanding machine, the line more comprehensively meets the post-processing requirements for various titanium alloy plates. The plate production line is capable of mass production of titanium and titanium alloys, zirconium and zirconium alloys, and other rare metal plates, with a thickness range of 0.4 to 120mm, width range of 800 to 2250mm, and length range of 2000 to 12500mm.

Forging System

We have introduced advanced 45/50MN and 20MN fast forging units, with up to 110 strikes/min, controlled by Siemens’ PLC system. This ensures precise control of forging parameters, with real-time monitoring via infrared temperature measurement and multi-camera surveillance.

These units enable us to produce titanium alloy bars from Ф80mm to Ф420mm, along with various titanium alloy forgings and billets. Our inspection system, provided by Spain’s Tainatong Company, guarantees 100% coverage and real-time imaging for bars ranging from 100mm to Ф500mm, ensuring precise and comprehensive quality control.

Additionally, our forging line is equipped with a full range of machining equipment, including lathes, CNC machines, and milling machines, to meet all machining requirements for titanium alloy products.

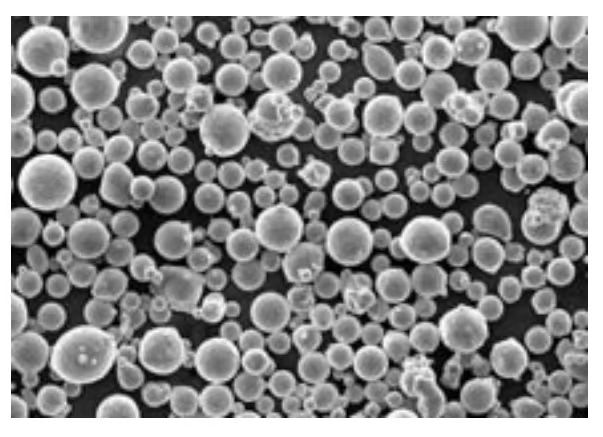

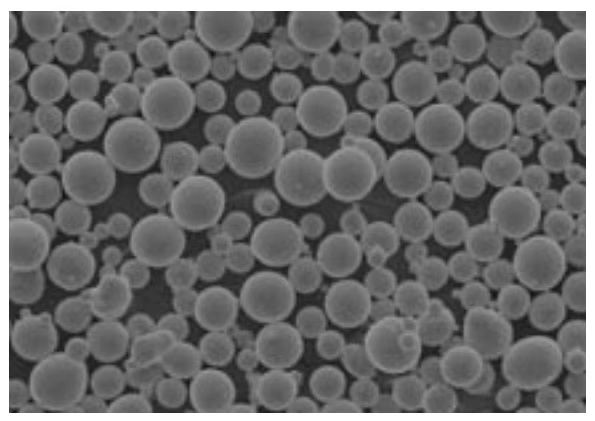

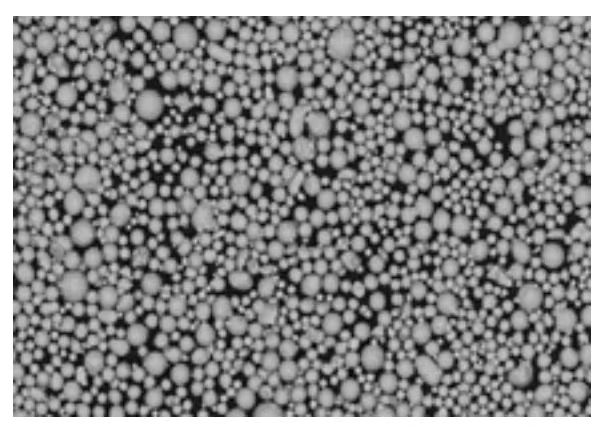

OEM and ODM are accepted,

Composition and particle size can be customized.

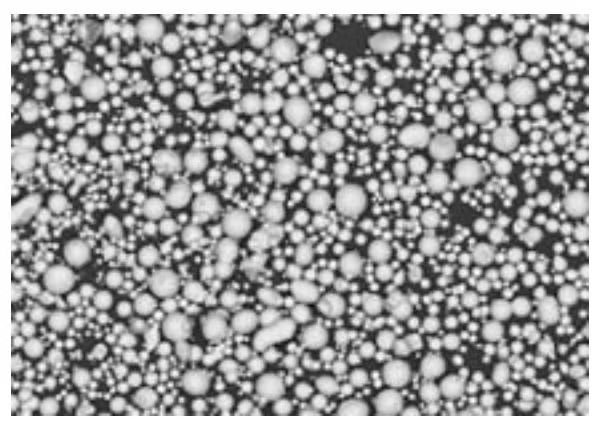

Titanium &Titanium Alloy Powders

TA1 , TC4 , TA15,TA15 ,TiAl4822, Ti2AlNb, NiTi50, TA17, TA18, TC11, TC19, TC31, etc.

High-Temperature Alloy Powders

GH3230 ,GH3536,GH3625,GH4099,GH4169,GH5188,M247、K438、M509、EP648、In939

FAQs

Can you produce customized cables based on our requirements?

What types of titanium alloy materials do you offer?

We offer a wide range of titanium and titanium alloy products, including cold-rolled and hot-rolled coils, sheets, plates, forgings, billets, rods, wires, tubes, pipes, and clad coils. Our products include grades such as TA1, TA2, TC4, TC6, as well as high-temperature alloys, aluminum alloys, stainless steel alloys, copper alloys, and medical cobalt-chromium alloy powders.

What industries are your titanium alloys used in?

Our titanium alloys are widely used in aerospace, automotive manufacturing, medical devices, petrochemical, military, and other high-tech industries. The materials we provide offer excellent corrosion resistance and high-temperature performance, making them suitable for demanding applications.

Do you offer customized services?

Yes, we provide both OEM and ODM services. We can customize titanium alloy products to meet specific requirements in terms of size, shape, composition, and performance, ensuring they meet the unique demands of various engineering projects.

How do you ensure the quality of your products?

We use advanced manufacturing equipment and strict quality control standards to ensure that every batch of product meets international quality requirements. Our laboratory is equipped with top-tier testing technology, and we perform comprehensive testing on every batch of material, including chemical composition, mechanical properties, and surface treatment, to ensure product consistency and high performance.

Do you offer small batch orders?

Yes, we support small batch orders, especially for custom projects or test materials. We understand the diverse needs of our clients and offer flexible purchasing options based on your specific requirements.

How can I get a quote or more information?

You can contact our online customer service or send an inquiry via email. Our team will respond to your request as quickly as possible and provide detailed pricing information.

What is your delivery lead time?

Our standard delivery time is typically 2-4 weeks, depending on the order size and customization requirements. For urgent orders, we also offer expedited processing services.

About Us

Metalchief specializes in the research, development, and production of metal powders and titanium alloys. We offer a wide range of products, including cold-rolled, hot-rolled, clad coils, forgings, plates, bars, and pipes, serving industries like aerospace, medical, energy, and automotive.

With advanced production technologies and strict quality control, we ensure consistent, high-performance materials that meet global standards. Our focus on innovation and quality makes us a trusted partner for industries requiring durable and reliable metal solutions.

Contact MetalChief

24/7 Global Support

Address:Room 701, Fengtin Building, Hefeng Creative Square, No. 375 Jiangdong North Road, Building 006 (7-1), Yinzhou District, Ningbo City, Zhejiang Province, China

Call Us: + 86 18668881072

Email Us:[email protected]