Contact MetalChief

24/7 Global Support

Address:Room 701, Fengtin Building, Hefeng Creative Square, No. 375 Jiangdong North Road, Building 006 (7-1), Yinzhou District, Ningbo City, Zhejiang Province, China

Email Us:[email protected]

The Ultimate Metal Solution

Revolutionizing Metal Manufacturing

Unlock the Future of Metal Manufacturing

Maximized Efficiency, Unmatched Excellence

Tailored to Your Needs

We have mastered core technologies such as the design and preparation of high-performance metal powder materials, intelligent additive manufacturing equipment and processes, and are committed to providing global users with comprehensive metal 3D printing solutions.

Custom Material Design, Powder Trial Production, Structural Optimization.

Technical Services: Forming Process, Heat Treatment, Surface Treatment Testing, Inspection and Analysis.

OEM and ODM are accepted,

Composition and particle size can be customized.

TA1 , TC4 , TA15,TA15 ,TiAl4822, Ti2AlNb, NiTi50, TA17, TA18, TC11, TC19, TC31, etc.

GH3230 ,GH3536,GH3625,GH4099,GH4169,GH5188,M247、K438、M509、EP648、In939

OEM and ODM are accepted

TA1(Gr.1),

TA2(Gr.2), TA3(Gr.3),

TA4(Gr.4),

TA8, TA9,

TA10(Gr.12),

TC4ELI(Gr.23) etc.

TA1(Gr.1),

AL:1050,1060,3003

Stainless Steel:304, 430

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA4(Gr.4), TA5,TA7(Gr.6), TA8, TA9(Gr.7),TA10(Gr.12), TA15(BT20), TC1,TC2, TC4(Gr.5), TC6, TC11, TC18,TB2,TB5,TB6,T165,

T160,R60700,R60702

TA1(Gr.1 ), TA2(Gr.2),TA3(Gr.3),TA4(Gr.4),TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11, TC17,TC18(BT22), C.P.Ti, Gr.11,Gr.17,TI-6AI-4VELI, TC10(Ti662),TA19(Ti6242),TC19(Ti6246),TC21(-Ti62222s),TB2,TB5,TB6(Ti1023)

TA1(Gr.1 ), TA2(Gr.2), TA3(Gr.3), TA4(Gr.4)TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11,TC17,TC18(BT22),C.P.Ti, Gr.11,Gr.17,Ti-6A1-4VELI, TC10(Ti662),TA19(-Ti6242),TC19(Ti6246),TC21(Ti62222s),TB2, TB5, TB6(Ti1023)

TA1(Gr.1), TA2(Gr.2),

TA3(Gr.3),TA10(Gr.12),

TA15(BT20),TA18(Gr.9),

TC4(Gr.5),C.P.Ti, Gr.11,

Gr.17,Ti-6AI-4VELI,

TC16,TB3,TB8,TB13 etc.

TA1(Gr.1), TA2(Gr.2), TA9(Gr.7),TA10(Gr.12), TA18(Gr.9), TC4(Gr.5),R60702 etc

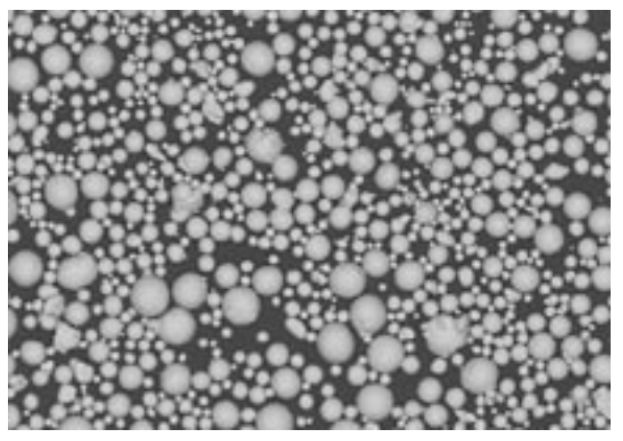

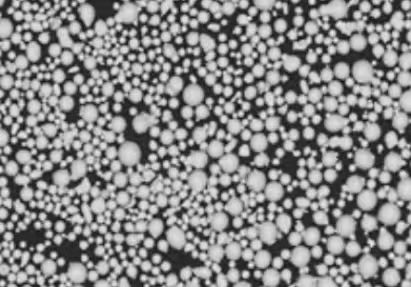

With 10years of experience in atomization powder-making technology and leveraging the country’s top laboratories, we have mastered world-leading powder production technologies. Notably, we pioneered the localization of plasma torch atomization, electrode induction melting, and gas atomization. Our titanium alloy, high-temperature alloy, and other powders are now industrialized and applied across various industries.

Through advanced materials and manufacturing technologies, we have served over 5,000 users, covering various application scenarios including aerospace, automotive, molds, medical, and consumer electronics.

Can you produce customized cables based on our requirements?

We offer a wide range of metal powders including titanium, titanium alloys, and other high-performance metals. Our powders are used in various industries such as aerospace, automotive, and medical applications.

Our metal powders come in various particle sizes depending on your specific needs. Typical ranges include fine powders with particle sizes from 1 microns to 100 microns. We can also offer custom particle size distribution based on client requirements.

Our metal powders are of high purity, typically ranging from 99% to 99.99% depending on the material. We ensure strict quality control to meet industry standards.

Yes, we offer customization of metal powders, including specific purity, particle size distribution, and packaging based on your unique requirements. Please contact our sales team for more details on custom orders.

1. Raw Material: Use pure metals to reduce impurities and optimize chemical composition for size consistency.

2. Gas Atomization: Adjust gas pressure, temperature, and melting point to control particle size.

3. Sieving & Classification: Sort powders by size using different mesh sieves.

4. Laser Granulometry: Monitor powder size in real-time and adjust processes as needed.

5. Cooling Rate: Control cooling rate to influence particle crystallization and size.

Our metal powders are produced using advanced techniques such as gas atomization and atomized powder processes, ensuring consistent quality and performance.

Our metal powders are commonly used in industries like aerospace, automotive, medical implants, and 3D printing. They are used for manufacturing parts through processes such as powder metallurgy, additive manufacturing, and coating applications.

To place an order or request a quote, please contact our sales team via email at [email protected] or through our website’s contact form. We will assist you with your order details, customization options, and shipping requirements.

The lead time for custom metal powder orders depends on the specifications and quantity. Typically, it ranges from 2 to 6 weeks. Please reach out to us for more accurate timelines based on your needs.

We conduct rigorous testing at every stage of production, including particle size analysis, purity testing, and flowability tests. Our quality assurance process ensures that our metal powders meet the highest industry standards.

Address:Room 701, Fengtin Building, Hefeng Creative Square, No. 375 Jiangdong North Road, Building 006 (7-1), Yinzhou District, Ningbo City, Zhejiang Province, China

Email Us:[email protected]

Send us a message if you have any questions or request a quote. We will be back to you ASAP!