Metal Powder &Materials Manufacturer Since 2014

Your Partner for Advanced Metal Manufacturing and Materials

We offer competitive metal powder prices, ensuring no impact from price fluctuations in long-term cooperation.

With top-tier laboratory facilities, we implement rigorous quality testing processes to ensure each batch meets the highest standards.

Whether you need bulk orders or small quantities, we can meet your needs with flexibility and efficiency.

Trusted by

High-Quality Metal Powder &Material Product Solutions

OEM and ODM are accepted,

Composition and particle size can be customized.

Titanium &Titanium Alloy Powders

TA1 , TC4 , TA15,TA15 ,

TiAl4822, Ti2AlNb, NiTi50, TA17, TA18, TC11, TC19, TC31, etc.

High-Temperature Alloy Powders

GH3230 ,GH3536,GH3625,GH4099,GH4169,GH5188,M247、K438、M509、EP648、In939

Aluminum Alloy Powders

AISi10Mg,AlMgErZr,Al、AISi7Mg、2024、2219

Tool Steel Powders

18Ni300 ,CX,PW01,420、H13、S136、1.2709

Stainless Steel Powders

17-4PH,316L,15-5PH,304L、310S、410

Copper Alloy Powders

CuCrZr,GRcop-42,CuSn10,GRcop-84、CuAlNiFe、CuNi2SiCr

Medical Cobalt-Chromium Alloy Powders

CoCr02(CoCrMo)

OEM and ODM are accepted

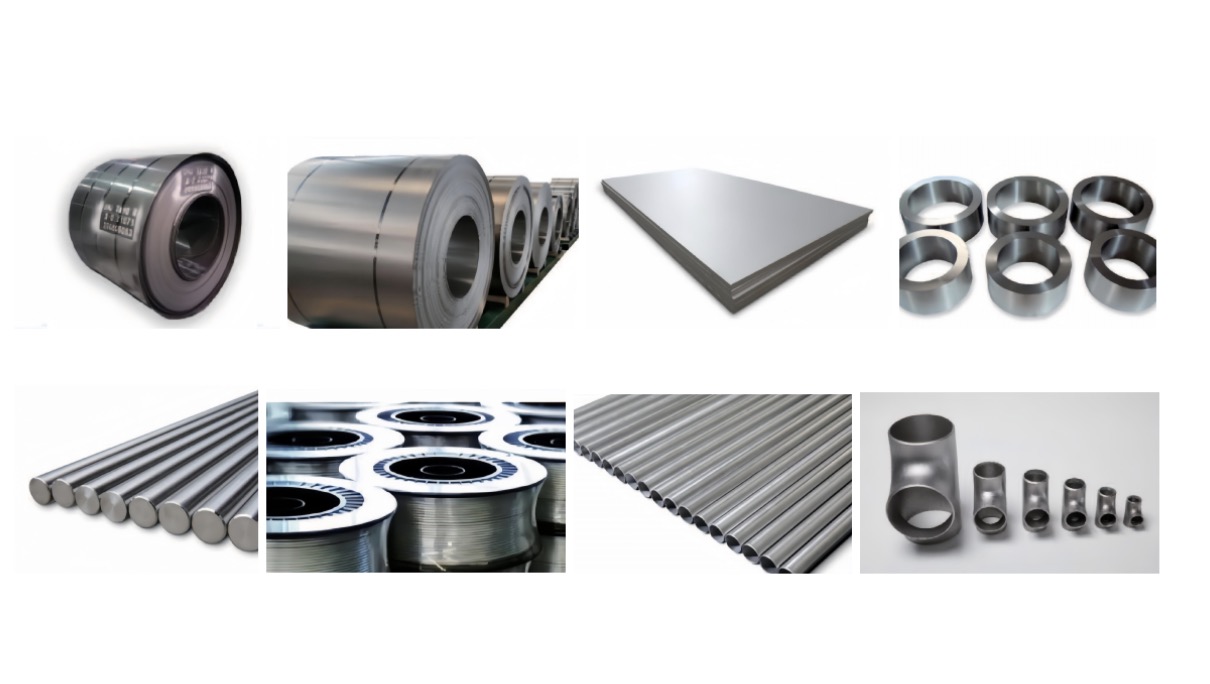

Cold &Hot Rolling Coil

TA1(Gr.1),

TA2(Gr.2), TA3(Gr.3),

TA4(Gr.4),

TA8, TA9,

TA10(Gr.12),

TC4ELI(Gr.23) etc.

Clad Coil

TA1(Gr.1),

AL:1050,1060,3003

Stainless Steel:304, 430

Sheet&Plate

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA4(Gr.4), TA5,TA7(Gr.6), TA8, TA9(Gr.7),TA10(Gr.12), TA15(BT20), TC1,TC2, TC4(Gr.5), TC6, TC11, TC18,TB2,TB5,TB6,T165,

T160,R60700,R60702

Forging

TA1(Gr.1 ), TA2(Gr.2),TA3(Gr.3),TA4(Gr.4),TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11, TC17,TC18(BT22), C.P.Ti, Gr.11,Gr.17,TI-6AI-4VELI, TC10(Ti662),TA19(Ti6242),TC19(Ti6246),TC21(-Ti62222s),TB2,TB5,TB6(Ti1023)

Billet Bar& Rod

TA1(Gr.1 ), TA2(Gr.2), TA3(Gr.3), TA4(Gr.4)TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11,TC17,TC18(BT22),C.P.Ti, Gr.11,Gr.17,Ti-6A1-4VELI, TC10(Ti662),TA19(-Ti6242),TC19(Ti6246),TC21(Ti62222s),TB2, TB5, TB6(Ti1023)

Wire

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA10(Gr.12),

TA15(BT20),TA18(Gr.9),

TC4(Gr.5),C.P.Ti, Gr.11, Gr.17,Ti-6AI-4VELI, TC16,TB3,TB8,TB13 etc.

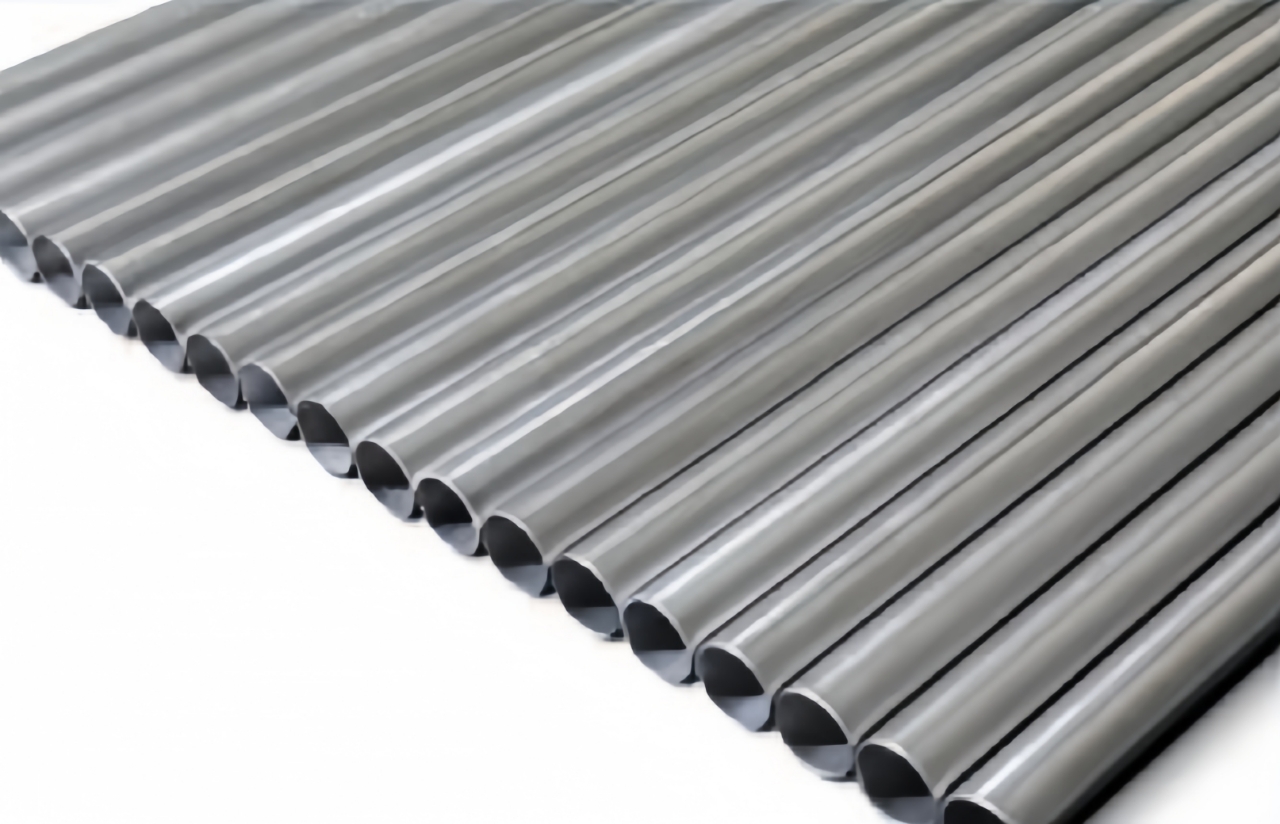

Tube Pipe

TA1(Gr.1), TA2(Gr.2), TA9(Gr.7),TA10(Gr.12), TA18(Gr.9), TC4(Gr.5),R60702 etc

Advanced Laboratory Equipment

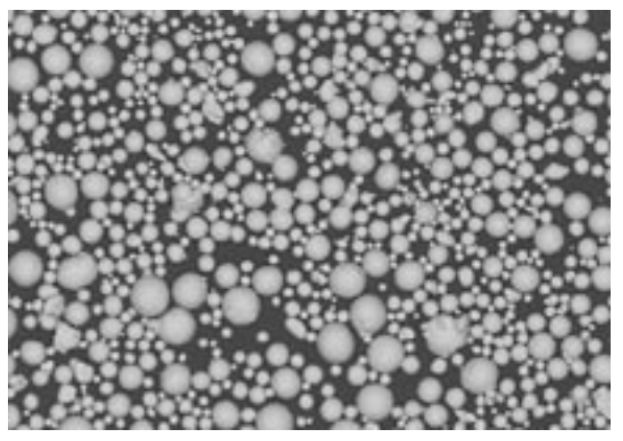

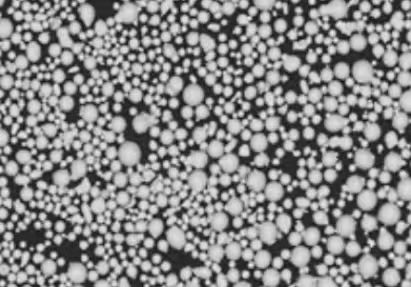

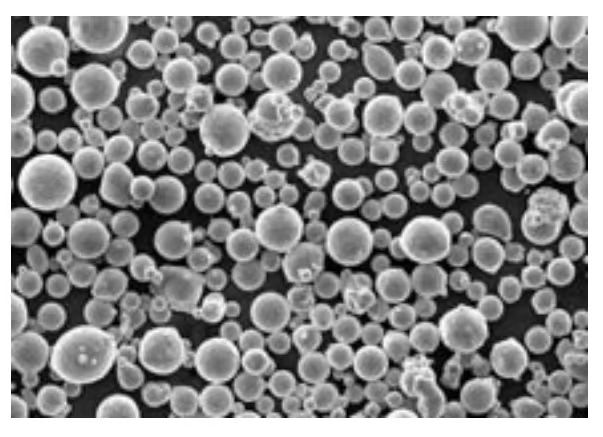

With 10years of experience in atomization powder-making technology and leveraging the country’s top laboratories, we have mastered world-leading powder production technologies. Notably, we pioneered the localization of plasma torch atomization, electrode induction melting, and gas atomization. Our titanium alloy, high-temperature alloy, and other powders are now industrialized and applied across various industries.

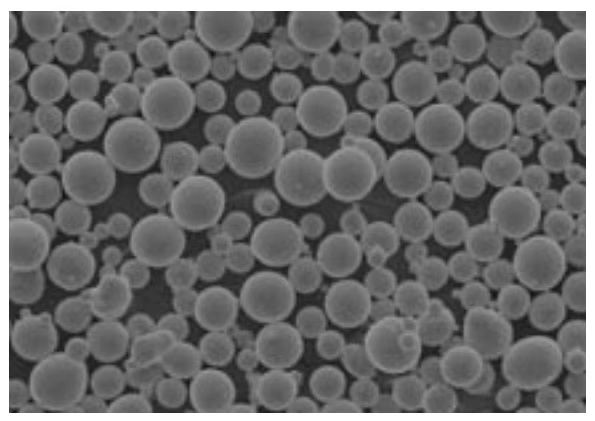

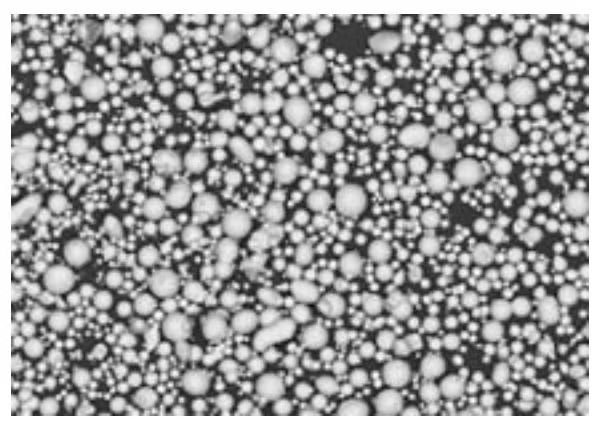

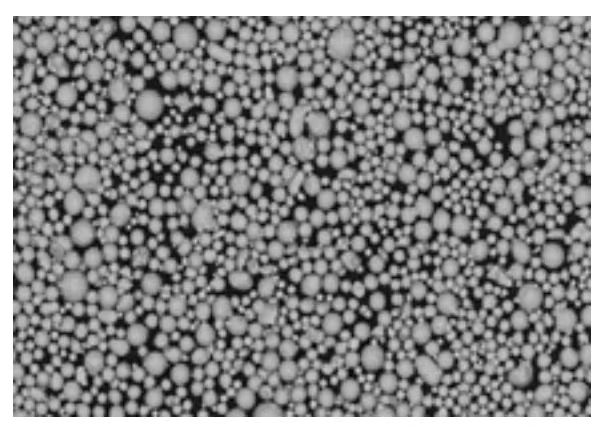

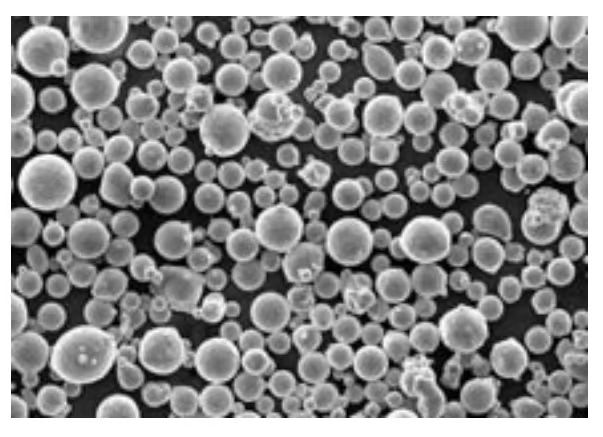

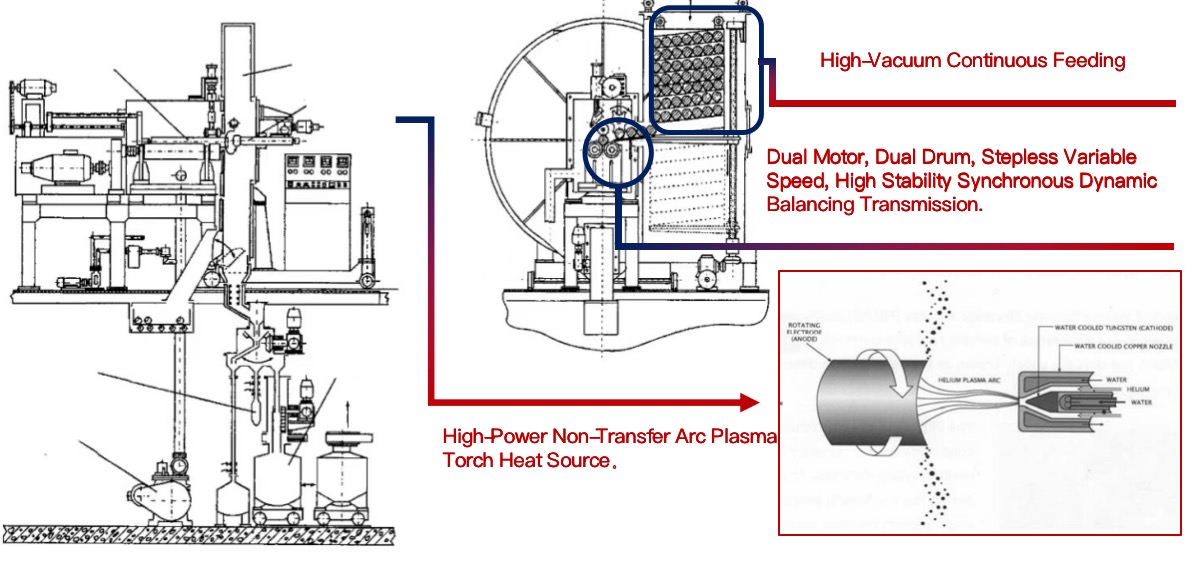

Ultra-High-Speed Rotating Electrode Atomization Powdering Technology

A unified particle size prediction technology for PREP powders has been developed. The integration of the hopper and atomization chamber enhances motor speed and dynamic balance at ultra-high rotational speeds, ensuring stable performance for metal billets.

Fine powder recovery is doubled, costs are reduced by over 50%, and the powder size is controllable for customizable production.

Leading the Way in Materials Production

We are a company that integrates research and development with production.

We possess first-class domestic and internationally advanced titanium and titanium alloy production facilities,

testing technologies, and a team of top-tier professionals.

Discover The Metalchief Advantage

Empowering Key Industries

Aerospace

Biomedical

Automotive Molds

Consumer Electronics

Mining Machinery

Oil & Power Generation

Steel Metallurgy

Scientific Research & Education

10+ years of expertise

Advanced Laboratory Equipment

Competitive pricing ensures quality and performance

Safety and reliability standards

Fully compliant with international certifications

FOCUS ON

Prompt Customer Support

OEM Solutions

Global Logistics Expertise

Rapid Manufacturing Lead Times

Project Management & Development

Dedicated After-Sales Support

Experience the METALCHIEF Difference

What Makes Us Unique?

At METALCHIEF, we combine cutting-edge technology, advanced laboratory equipment, and innovative manufacturing systems to deliver high-quality metal powders. Our skilled workforce ensures precision and excellence, while our 24/7 consultation service guarantees continuous support for our clients. With our commitment to quality and customer satisfaction, we are the trusted partner in metal powder solutions.

Exploring AlMgErZr Alloy Powder: Key Characteristics, Uses, and Advantages

AlMgErZr alloy powder is gaining increasing attention for its exceptional properties. This article will explore the key characteristics, uses, and the advantages it offers across

News & Insight

Exploring AlMgErZr Alloy Powder: Key Characteristics, Uses, and Advantages

AlMgErZr alloy powder is gaining increasing attention for its exceptional

TA1 Titanium Alloy Powder: Ideal for High-Performance Aerospace and Industrial Applications

Titanium alloy powder is revolutionizing aerospace and industrial applications. Let’s

CoCr01 Alloy Powder: Explore Its Exceptional Wear Resistance and Durability

CoCr01 alloy powder is known for its exceptional wear resistance