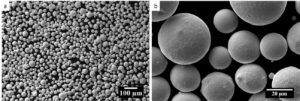

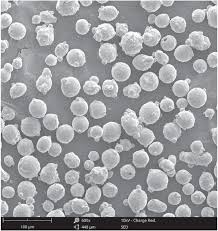

18Ni300 tool steel powder stands out as one of the best choices for industries requiring high toughness and precision. Whether you're in automotive, aerospace, or manufacturing, understanding the benefits of 18Ni300 can elevate your material choices. But what exactly makes it so unique compared to other tool steels?

18Ni300 is renowned for its toughness and resistance to wear, making it ideal for precision engineering and high-stress applications[1].

Let’s explore why 18Ni300 is considered one of the best tool steels for demanding applications.

What is the best tool steel for toughness?

Toughness in tool steel is crucial, especially when dealing with high-stress applications. 18Ni300 is one of the top contenders due to its excellent mechanical properties.

18Ni300 tool steel excels in toughness, resisting cracking even under high-stress conditions[2].

When it comes to tool steel, toughness is one of the most important characteristics. It determines how well the material can withstand impact or stress without fracturing. 18Ni300 tool steel is considered one of the best in terms of toughness due to its high nickel content, which gives the alloy remarkable resilience[3]. The nickel improves its ability to withstand harsh conditions, preventing cracks from forming under stress or impact.

In high-performance applications, such as the automotive or aerospace industries, components are constantly subjected to high stress and temperatures. This is where 18Ni300 shines. It maintains its toughness and mechanical properties even when exposed to extreme conditions, ensuring that parts last longer and perform better[4]. For instance, in the automotive industry, 18Ni300 is commonly used for manufacturing high-performance engine components, where both toughness and precision are required.

Another key factor contributing to its toughness is its ability to maintain strength at elevated temperatures. Unlike some tool steels that lose their toughness when exposed to heat, 18Ni300 performs exceptionally well under high temperatures, making it a preferred choice in industries that require durability under heat stress.

| Property | 18Ni300 Tool Steel | Benefits |

|---|---|---|

| Toughness | High resistance to fracture | Ideal for high-stress conditions |

| Temperature Strength | Maintains strength at elevated temperatures | Suitable for high-performance tools |

| Machinability | Good machinability | Easy to manufacture into precise shapes |

What makes 18Ni300 Tool Steel unique?

The uniqueness of 18Ni300 comes from its high alloy content and how it behaves in high-stress applications.

18Ni300’s unique blend of toughness and wear resistance ensures high durability and performance in precise, high-stress environments[5].

The composition of 18Ni300 tool steel is what makes it stand out from the rest. This alloy is particularly known for its high nickel content, which accounts for its high toughness and wear resistance[6]. The nickel enhances the steel’s ability to withstand mechanical stress, impact, and extreme temperatures without compromising its performance.

Additionally, 18Ni300 tool steel is highly resistant to wear, making it ideal for precision cutting tools. In industries where wear resistance is a critical factor, such as in aerospace and automotive manufacturing, 18Ni300 offers an excellent balance between hardness and toughness. Its ability to withstand repetitive stress while maintaining its strength makes it ideal for tools that need to endure constant wear and tear.

Moreover, 18Ni300 has excellent machinability, meaning that manufacturers can easily work with it to create complex shapes or designs[7]. This is particularly important in industries like aerospace, where components need to be precisely manufactured to meet stringent performance and safety standards.

How the composition of 18Ni300 contributes to its properties

18Ni300 tool steel contains not only nickel but also other key elements that further enhance its performance. These include:

- Carbon (C): Responsible for the overall hardness and strength of the steel. The higher the carbon content, the harder the steel becomes.

- Manganese (Mn): Helps in deoxidizing the steel and improving its toughness.

- Chromium (Cr): Improves corrosion resistance and increases the steel's overall strength.

- Vanadium (V): Used to refine the grain structure, improving wear resistance and toughness.

The combination of these elements makes 18Ni300 a highly versatile and durable alloy for use in many demanding industries.

| Alloy Composition | Nickel Content | Key Properties |

|---|---|---|

| 18Ni300 | High | Toughness, wear resistance, hardness |

| Carbon (C) | Moderate | Strength and hardness |

| Manganese (Mn) | Low | Toughness |

| Chromium (Cr) | Low | Corrosion resistance |

How does 18Ni300 compare to other tool steels?

18Ni300’s combination of toughness, wear resistance, and temperature strength makes it superior in many ways when compared to other tool steels.

18Ni300 offers superior toughness and durability compared to many other common tool steels, making it ideal for precision tools[8].

When comparing 18Ni300 to other tool steels such as D2, A2, or O1, several factors set it apart. While D2 and A2 tool steels are known for their hardness, 18Ni300 excels in toughness, making it more suitable for high-stress applications. For example, D2 steel, while excellent for cutting tools due to its hardness, lacks the same level of toughness[9]. As a result, tools made from D2 steel may be prone to cracking under extreme conditions.

18Ni300, on the other hand, is designed to resist such cracks, ensuring that it maintains its integrity even in high-impact applications. The higher nickel content gives it superior toughness, preventing fractures that could result in tool failure.

Another comparison can be made with O1 tool steel, which is a high-carbon steel that is known for its hardness and wear resistance. While O1 steel is highly effective in some applications, it doesn’t offer the same level of toughness or wear resistance at elevated temperatures as 18Ni300[10]. This is why 18Ni300 is favored in industries like aerospace, where components must perform under both high-stress and high-temperature conditions.

| Tool Steel Type | Key Properties | Comparison with 18Ni300 |

|---|---|---|

| D2 Tool Steel | Hardness, wear resistance | Lacks the toughness of 18Ni300 |

| A2 Tool Steel | Toughness, wear resistance | Less durable at elevated temperatures |

| O1 Tool Steel | High hardness, wear resistance | Not as tough or temperature resistant as 18Ni300 |

| 18Ni300 | Toughness, wear resistance, high-temperature strength | Superior toughness and wear resistance |

Applications of 18Ni300 Tool Steel

18Ni300 tool steel is widely used in a variety of industries where toughness, wear resistance, and high performance are essential.

18Ni300 is perfect for applications in high-performance industries such as automotive, aerospace, and manufacturing[11].

The primary industries that utilize 18Ni300 tool steel are aerospace, automotive, and manufacturing. In aerospace, the need for lightweight yet durable materials is critical, as parts must perform under extreme conditions while maintaining structural integrity. 18Ni300’s combination of toughness and temperature strength makes it perfect for engine components, landing gear, and other high-stress parts.

Similarly, in the automotive industry, 18Ni300 is used to produce precision cutting tools, such as dies and molds, that must withstand repeated use without degrading. The alloy’s ability to resist wear and maintain its strength at high temperatures makes it an ideal material for manufacturing automotive parts that require high precision and durability.

In manufacturing, 18Ni300 is often used in the production of tooling and dies for processes such as stamping and forging. Its high wear resistance ensures that these tools maintain their effectiveness over long production runs, reducing the need for frequent tool replacements.

| Industry | Key Application | Benefits |

|---|---|---|

| Aerospace | Engine parts, landing gear | High strength, temperature resistance |

| Automotive | Dies, molds, engine components | Precision, durability |

| Manufacturing | Stamping, forging tools | Wear resistance, longevity |

Conclusion

18Ni300 tool steel offers an excellent balance of toughness, wear resistance, and high-temperature strength, making it the perfect material for demanding applications in multiple industries.

[1]: 18Ni300 is renowned for its ability to withstand wear and stress, providing reliable performance in high-demand applications.

[2]: The toughness of 18Ni300 ensures that it does not crack easily, making it perfect for use in high-stress environments.

[3]: High nickel content is key in providing 18Ni300 its superior toughness, resilience, and ability to handle harsh conditions.

[4]: 18Ni300’s strength at high temperatures ensures that it performs well even in the most demanding conditions.

[5]: The unique properties of 18Ni300 make it perfect for precise engineering and demanding high-stress environments.

[6]: 18Ni300’s high nickel content improves wear resistance and toughness, making it highly reliable in high-stress applications.

[7]: The alloy’s machinability allows for complex shapes, which is particularly useful in the aerospace industry.

[8]: 18Ni300 outperforms many other tool steels in terms of toughness and durability, making it ideal for high-performance tools.

[9]: D2 is hard but lacks the toughness of 18Ni300, making it prone to cracking under certain conditions.

[10]: O1 steel is less resistant to temperature and impact compared to 18Ni300, which is why the latter is preferred in high-stress environments.

[11]: 18Ni300 is widely used in industries like aerospace and automotive due to its exceptional toughness, wear resistance, and ability to perform under extreme conditions.