CuCrZr alloy powder is renowned for its impressive combination of strength, electrical conductivity, and resistance to wear. But what exactly makes this material a top choice for various industries? Let's dive into the properties and benefits of CuCrZr, one of the most versatile copper alloys.

CuCrZr is prized for its exceptional strength and electrical conductivity, making it ideal for high-performance applications.

In this article, we’ll explore why CuCrZr stands out as a reliable choice for industries demanding high strength and durability.

What are the properties of CuCrZr?

CuCrZr is a copper-chromium-zirconium alloy with distinctive properties that make it highly suitable for demanding applications, particularly in the electrical and manufacturing industries.

CuCrZr combines strength, conductivity, and resistance to wear, making it essential for high-performance components.

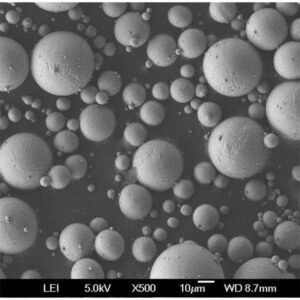

CuCrZr is a copper alloy that incorporates small amounts of chromium and zirconium. These additions provide remarkable improvements in the mechanical properties of copper, particularly its strength and resistance to wear. Copper itself is an excellent conductor of electricity, but it lacks the strength needed in some high-stress applications. By adding chromium and zirconium, the alloy gains enhanced durability while still maintaining excellent electrical conductivity.

The unique blend of copper, chromium, and zirconium allows CuCrZr to perform well under high temperatures and stress. Chromium, for example, improves the hardness of the alloy, while zirconium increases its resistance to heat and corrosion. This makes CuCrZr suitable for industries like power generation, electrical engineering, and automotive, where both strength and conductivity are critical.

| Property | CuCrZr Alloy | Benefits |

|---|---|---|

| Electrical Conductivity | High | Ideal for electrical components |

| Strength | High | Suitable for high-stress conditions |

| Wear Resistance | Excellent | Durable in demanding environments |

| Temperature Resistance | Good | Performs well under heat stress |

What makes CuCrZr Alloy unique?

The composition of CuCrZr alloy gives it several unique advantages, setting it apart from other copper alloys.

CuCrZr’s alloying elements offer enhanced strength and wear resistance, making it perfect for demanding applications.

CuCrZr stands out due to its carefully balanced composition of copper, chromium, and zirconium. Copper is known for its excellent conductivity, which is crucial in many electronic and electrical components. However, its inherent softness limits its use in high-stress environments. Adding chromium improves the alloy’s hardness and strength, while zirconium enhances its ability to withstand heat and wear.

These properties are especially useful in applications where the material is exposed to harsh environments. For example, CuCrZr is often used in welding electrodes, electrical contacts, and heat exchangers. Its combination of strength, conductivity, and resistance to high temperatures ensures that these components perform optimally over time.

In welding applications, the alloy’s strength allows it to maintain its shape under the high pressure and temperatures generated during welding processes. The electrical conductivity, on the other hand, ensures that it remains effective for long-term electrical applications. Additionally, CuCrZr is resistant to corrosion, ensuring its longevity even in demanding conditions.

| Alloy Composition | Copper Content | Chromium Content | Zirconium Content |

|---|---|---|---|

| CuCrZr | High | Moderate | Low |

How does CuCrZr compare to other copper alloys?

CuCrZr’s combination of strength, conductivity, and durability gives it distinct advantages when compared to other copper alloys like C11000 or C18000.

CuCrZr offers superior wear resistance and strength, making it more suitable for high-stress applications than many other copper alloys.

When compared to other copper alloys, CuCrZr demonstrates superior performance in certain areas, particularly in terms of strength and wear resistance. For example, C11000 copper, often used in electrical applications, has excellent conductivity but lacks the strength required in high-stress environments. Similarly, C18000, a copper-chromium alloy, offers improved strength but may not provide the same level of conductivity as CuCrZr.

CuCrZr, with its unique blend of chromium and zirconium, offers an optimal balance of these two critical properties—strength and conductivity. Its resistance to wear also makes it a more durable option in environments subject to repetitive stress or high temperatures. This is why CuCrZr is often chosen for components like electrical contacts, welding electrodes, and automotive parts where both conductivity and strength are essential.

| Copper Alloy Type | Strength | Conductivity | Wear Resistance |

|---|---|---|---|

| C11000 Copper | Low | Very High | Low |

| C18000 Copper-Chromium | Moderate | High | Moderate |

| CuCrZr Alloy | High | High | Excellent |

Applications of CuCrZr Alloy Powder

CuCrZr alloy powder is used in a wide range of industries, from electrical engineering to automotive and aerospace applications, where its unique properties offer significant advantages.

CuCrZr alloy powder is commonly used in industries requiring high strength, conductivity, and wear resistance, such as aerospace and automotive.

One of the most common applications for CuCrZr alloy powder is in the manufacturing of welding electrodes. These electrodes require high strength and conductivity to withstand the extreme temperatures and forces generated during welding. CuCrZr's strength ensures that the electrode does not degrade over time, while its conductivity allows it to transfer electrical currents effectively.

In the automotive industry, CuCrZr is used for high-performance electrical components, such as electrical contacts and connectors. These components need to maintain both electrical conductivity and durability under stress. CuCrZr is also found in heat exchangers, where its resistance to heat and corrosion is critical for ensuring the longevity and performance of the system.

Additionally, in the aerospace industry, CuCrZr alloy powder is used in various parts that are exposed to high temperatures and pressures, such as engine components and turbine blades. The material’s strength and temperature resistance make it ideal for these high-demand applications.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Electrical components | High conductivity, durability |

| Aerospace | Engine parts, turbine blades | High strength, temperature resistance |

| Welding Industry | Electrodes | Wear resistance, conductivity |

Conclusion

CuCrZr alloy powder’s combination of strength, conductivity, and durability makes it the perfect choice for demanding applications across multiple industries.

[1]: CuCrZr is a copper-chromium-zirconium alloy that combines copper's excellent conductivity with the strength and wear resistance provided by chromium and zirconium.

[2]: Chromium is added to copper alloys to improve hardness, while zirconium enhances heat and corrosion resistance.

[3]: CuCrZr is often used in high-performance welding applications due to its strength and ability to conduct electricity without degradation.

[4]: The comparison of CuCrZr to other alloys like C11000 and C18000 highlights its superior properties for high-stress and high-temperature applications.

[5]: CuCrZr’s application in industries like automotive, aerospace, and welding is a testament to its versatility and durability.