CoCr01 alloy powder is known for its exceptional wear resistance and durability. But what makes it such a standout material in demanding industrial applications? Let’s dive into the properties of CoCr01 alloy and its key advantages.

CoCr01 alloy powder excels in wear resistance and durability, making it a reliable choice for high-performance applications.

In this article, we’ll explore why CoCr01 alloy powder stands out in industries requiring durable materials.

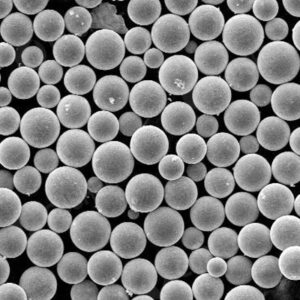

What is CoCr01 Alloy Powder?

CoCr01 is a cobalt-chromium alloy known for its superior strength, wear resistance, and high-temperature durability. It's widely used in applications that demand exceptional performance in extreme conditions.

CoCr01 offers outstanding wear resistance, strength, and heat resistance, making it ideal for industrial applications.

CoCr01 alloy is composed of cobalt, chromium, and small amounts of other elements. The combination of these materials results in an alloy that has excellent wear resistance and the ability to withstand high temperatures and corrosive environments.

Cobalt, the primary element in CoCr01, provides excellent strength and hardness. Chromium contributes to the alloy's corrosion resistance, while small amounts of other elements further enhance the material’s mechanical properties. Together, these elements make CoCr01 suitable for use in industries like aerospace, automotive, and medical applications.

In high-performance applications such as turbine blades or orthopedic implants, CoCr01’s resistance to wear and corrosion is crucial for ensuring long-term reliability.

| Property | CoCr01 Alloy | Benefits |

|---|---|---|

| Wear Resistance | Excellent | Suitable for high-stress, high-wear environments |

| Strength | High | Ideal for load-bearing applications |

| Corrosion Resistance | High | Performs well in harsh environments |

| Temperature Resistance | Excellent | Withstands extreme heat |

Why Is CoCr01 Alloy Ideal for High-Wear Applications?

CoCr01’s exceptional wear resistance makes it perfect for components that face repeated friction or harsh conditions.

CoCr01 is known for its durability under high-stress conditions, making it perfect for wear-intensive applications.

The wear resistance of CoCr01 is a result of its unique composition. Cobalt is particularly effective in maintaining the integrity of the alloy under friction and stress. In environments where other materials might degrade, CoCr01 retains its strength and hardness.

This makes it ideal for use in bearings, valves, and seals—components that undergo constant friction. In the automotive industry, for instance, CoCr01 is used for high-performance engine parts and gear systems. These parts are exposed to high forces and friction, making wear resistance a critical property.

The high wear resistance also extends to CoCr01’s performance in medical devices, particularly joint replacements and dental implants. These devices are subject to constant mechanical stress, and CoCr01’s durability ensures that they remain effective over time, minimizing the need for replacements.

| Application | Industry | Benefit |

|---|---|---|

| Bearings | Automotive, Aerospace | High wear resistance |

| Engine Parts | Automotive | Durable under high stress |

| Joint Implants | Medical | Long-lasting under stress |

How Does CoCr01 Compare to Other Alloys in Terms of Durability?

CoCr01 stands out in terms of durability when compared to other alloys like stainless steel or titanium alloys.

CoCr01 outperforms many other alloys in wear resistance and strength, making it a top choice for demanding applications.

When compared to alloys such as stainless steel or titanium, CoCr01 consistently demonstrates superior durability in high-stress applications. Stainless steel, while resistant to corrosion, does not match CoCr01’s wear resistance. Titanium alloys, known for their lightness, offer some wear resistance but fall short in high-wear environments.

In contrast, CoCr01’s combination of cobalt and chromium gives it an edge, especially in high-friction environments. Whether in aerospace turbines, automotive engines, or medical devices, CoCr01 provides superior wear resistance, strength, and longevity compared to other materials.

This makes CoCr01 a preferred choice in industries where component longevity is critical, such as aerospace, medical devices, and heavy-duty machinery. The alloy’s high-temperature and wear resistance properties ensure that parts continue to perform effectively under extreme conditions.

| Alloy Type | Wear Resistance | Strength | Temperature Resistance |

|---|---|---|---|

| Stainless Steel | Moderate | Moderate | High |

| Titanium Alloys | High | High | Moderate |

| CoCr01 Alloy | Excellent | High | Excellent |

Applications of CoCr01 Alloy Powder

CoCr01 alloy powder is used in a variety of industries where wear resistance, strength, and durability are essential.

CoCr01 alloy powder is used in demanding industries like aerospace, automotive, and medical devices for its wear resistance and durability.

The main applications of CoCr01 alloy powder include aerospace components, automotive parts, and medical implants.

In aerospace, CoCr01 is used in parts such as turbine blades and nozzles, which are exposed to extreme heat and stress. In automotive, CoCr01 is commonly found in high-performance engine components and gears. These parts require materials that can withstand constant friction and high temperatures.

Medical applications of CoCr01 include joint replacements, dental implants, and surgical instruments. CoCr01’s wear resistance is crucial in medical devices, ensuring that they maintain their functionality and integrity over long periods. The alloy is also biocompatible, making it ideal for long-term use in the human body.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Turbine blades, nozzles | High temperature and wear resistance |

| Automotive | Engine components, gears | Durability under stress, wear resistance |

| Medical | Implants, surgical tools | Wear resistance, biocompatibility |

Conclusion

CoCr01 alloy powder’s exceptional durability and wear resistance make it an excellent choice for demanding applications across industries.

[1]: CoCr01 is a cobalt-chromium alloy known for its superior wear resistance and high-temperature durability. Learn more about its composition and properties.

[2]: The wear resistance of CoCr01 is especially valuable for components like bearings and engine parts, which endure constant friction. Find out more about its application in high-wear environments.

[3]: CoCr01 has a clear edge over other alloys like stainless steel and titanium due to its durability. Learn why it’s preferred in high-stress applications.

[4]: Applications like aerospace and medical devices rely on CoCr01’s wear resistance and biocompatibility. Read more on its diverse uses.