AlMgErZr alloy powder is gaining increasing attention for its exceptional properties. This article will explore the key characteristics, uses, and the advantages it offers across different industries, with a special focus on aerospace and industrial applications.

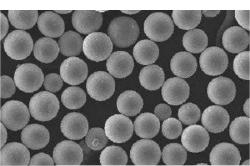

AlMgErZr alloy powder is a versatile material known for its strength, corrosion resistance, and lightweight nature. These qualities make it an ideal choice for high-performance sectors.

The growing demand for efficient and durable materials in sectors such as aerospace, automotive, and manufacturing has accelerated the adoption of AlMgErZr powder. Let’s dive deeper into why this alloy stands out and how it enhances innovation across industries.

We will now look at the main features of AlMgErZr alloy powder and how it offers a competitive edge in various applications. Let’s first explore why this material is so crucial for the aerospace industry.

Why is AlMgErZr Alloy Powder Ideal for Aerospace Applications?

The aerospace industry is known for its demanding material requirements. Parts must withstand extreme conditions such as high pressures, fluctuating temperatures, and intense mechanical stress. AlMgErZr alloy powder has emerged as a perfect candidate for such critical applications due to its superior strength and lightness.

AlMgErZr alloy powder[1] is crucial for aerospace due to its high strength-to-weight ratio and superior corrosion resistance.

High-Performance in Aerospace Applications

Aerospace components face extreme conditions during flight, with constant exposure to high altitudes, temperature fluctuations, and pressure. The performance of materials under such stress is paramount. AlMgErZr alloy powder provides a combination of strength and lightness that makes it ideal for aerospace applications, such as airframes, fuselages, and engine components.

The lightweight nature of AlMgErZr alloy reduces the overall weight of aircraft, which directly contributes to fuel efficiency and reduced operating costs. Its strength ensures that aircraft parts can withstand the mechanical stresses encountered during flight, contributing to the overall safety and longevity of the aircraft.

Key Properties for Aerospace Performance

| Property | AlMgErZr Alloy Powder |

|---|---|

| Strength-to-weight ratio | High |

| Corrosion resistance | Excellent |

| Temperature tolerance | High |

| Durability | Exceptional |

In addition to its structural benefits, the alloy’s corrosion resistance is highly beneficial in the aerospace sector. Aircraft parts are exposed to moisture, salt, and other corrosive elements, making AlMgErZr an excellent choice for long-lasting components. This ability to withstand harsh environmental conditions ensures that parts made from AlMgErZr alloy require less maintenance and have a longer lifespan.

AlMgErZr alloy is particularly popular in the production of parts that are exposed to high temperatures, such as turbine blades, engine components, and exhaust systems. These parts must maintain their strength and shape even when subjected to extreme conditions, making AlMgErZr powder an indispensable material in aerospace manufacturing.

Real-World Applications in Aerospace

A few examples of how AlMgErZr alloy powder is used in the aerospace industry include:

- Airframe Components: The alloy’s high strength and low weight make it ideal for manufacturing parts such as wing spars and fuselage sections.

- Turbine Blades: AlMgErZr’s ability to withstand high temperatures and corrosion makes it perfect for turbine blades that operate in extreme conditions.

- Engine Components: Components like pistons, engine housings, and compressors benefit from the alloy’s durability and thermal stability.

What Are the Industrial Uses of AlMgErZr Alloy Powder?

In industries such as automotive, energy, and manufacturing, AlMgErZr alloy powder is being used to develop materials that can endure high levels of stress while maintaining efficiency and performance. Its ability to resist wear and corrosion makes it an ideal material for parts that operate in tough environments.

AlMgErZr alloy powder[2] is increasingly used in industrial applications where high strength, lightweight, and resistance to environmental stress are needed.

Durability and Efficiency in Industrial Sectors

Durability is a key factor when selecting materials for industrial applications. AlMgErZr alloy powder’s inherent resistance to corrosion, wear, and extreme conditions makes it a perfect choice for critical components in industries like automotive, oil and gas, and construction.

In the automotive industry, the focus is on reducing vehicle weight to improve fuel efficiency and performance. AlMgErZr alloy powder is used to manufacture lightweight yet strong parts, such as engine blocks, chassis components, and suspension parts. The alloy’s corrosion resistance also ensures these parts last longer and require less maintenance.

Industrial Applications of AlMgErZr Alloy Powder

| Industry | Application | Benefit |

|---|---|---|

| Automotive | Engine parts, chassis | Weight reduction, strength |

| Oil and Gas | Pumps, valves, turbine components | Corrosion resistance, durability |

| Energy | Structural components | High performance under stress |

In the oil and gas industry, AlMgErZr powder is used in the production of valves, pumps, and seals, which are often exposed to high pressure and corrosive environments. The material’s resistance to corrosion and wear extends the lifespan of these components, which helps reduce maintenance costs and downtime.

Moreover, AlMgErZr alloy powder is used in the manufacturing of components in the energy sector, including turbines, compressors, and reactor components. These parts operate in extreme environments and require materials that can handle high temperatures and mechanical stress. AlMgErZr alloy’s ability to perform under such conditions makes it an essential material in the energy sector.

What Makes AlMgErZr Alloy Powder a Game-Changer for Additive Manufacturing?

Additive manufacturing, or 3D printing, has revolutionized the way parts are designed and produced. AlMgErZr alloy powder has proven to be a game-changer in this area due to its suitability for 3D printing processes, offering design flexibility and material efficiency.

AlMgErZr alloy powder[3] is increasingly being used in additive manufacturing due to its ability to produce lightweight yet strong and durable parts.

Additive Manufacturing and the Future of AlMgErZr Alloy Powder

Additive manufacturing allows for the creation of complex geometries that were previously impossible or too expensive to produce using traditional manufacturing techniques. AlMgErZr alloy powder is ideal for this process, as it can be used to print parts with intricate designs that are lightweight yet retain their strength.

The benefits of additive manufacturing with AlMgErZr alloy powder include:

- Customization: Parts can be designed and produced according to specific requirements, allowing for custom components for industries like aerospace and automotive.

- Material Efficiency: 3D printing minimizes material waste, making the manufacturing process more cost-effective and environmentally friendly.

- Complex Geometries: The powder can be used to create parts with complex shapes and internal structures, offering design flexibility that traditional manufacturing methods cannot match.

AlMgErZr alloy powder’s performance in additive manufacturing continues to open up new possibilities for industries that require precision-engineered parts, such as medical device manufacturing and high-performance automotive parts.

Conclusion

AlMgErZr alloy powder is a high-performance material that combines strength, durability, and lightweight properties. Its versatility makes it an ideal choice for aerospace, automotive, and industrial applications, providing solutions for some of the toughest material challenges across industries.

[1]: The strength and lightweight characteristics of AlMgErZr alloy powder make it ideal for aerospace applications, improving fuel efficiency and reducing operational costs.

[2]: AlMgErZr alloy powder is used in industrial applications like automotive, oil and gas, and energy sectors, offering durability, strength, and corrosion resistance in harsh environments.

[3]: Additive manufacturing with AlMgErZr alloy powder provides customization and material efficiency, allowing for complex geometries and high-performance components.