One-Stop Solution Provider for Metal Additive Manufacturing, Materials, and Processes.

Trusted by

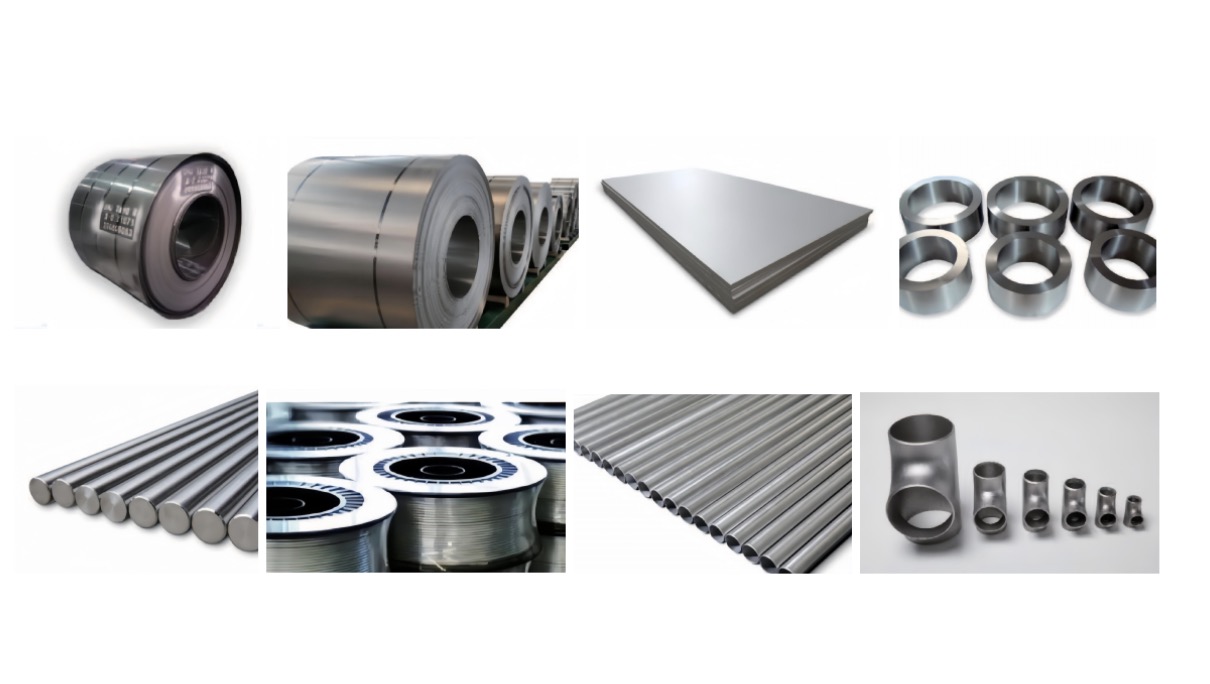

High-Quality Metal Powder &Material Product Solutions

OEM and ODM are accepted,

Composition and particle size can be customized.

Titanium &Titanium Alloy Powders

TA1 , TC4 , TA15,TA15 ,

TiAl4822, Ti2AlNb, NiTi50, TA17, TA18, TC11, TC19, TC31, etc.

High-Temperature Alloy Powders

GH3230 ,GH3536,GH3625,GH4099,GH4169,GH5188,M247、K438、M509、EP648、In939

OEM and ODM are accepted

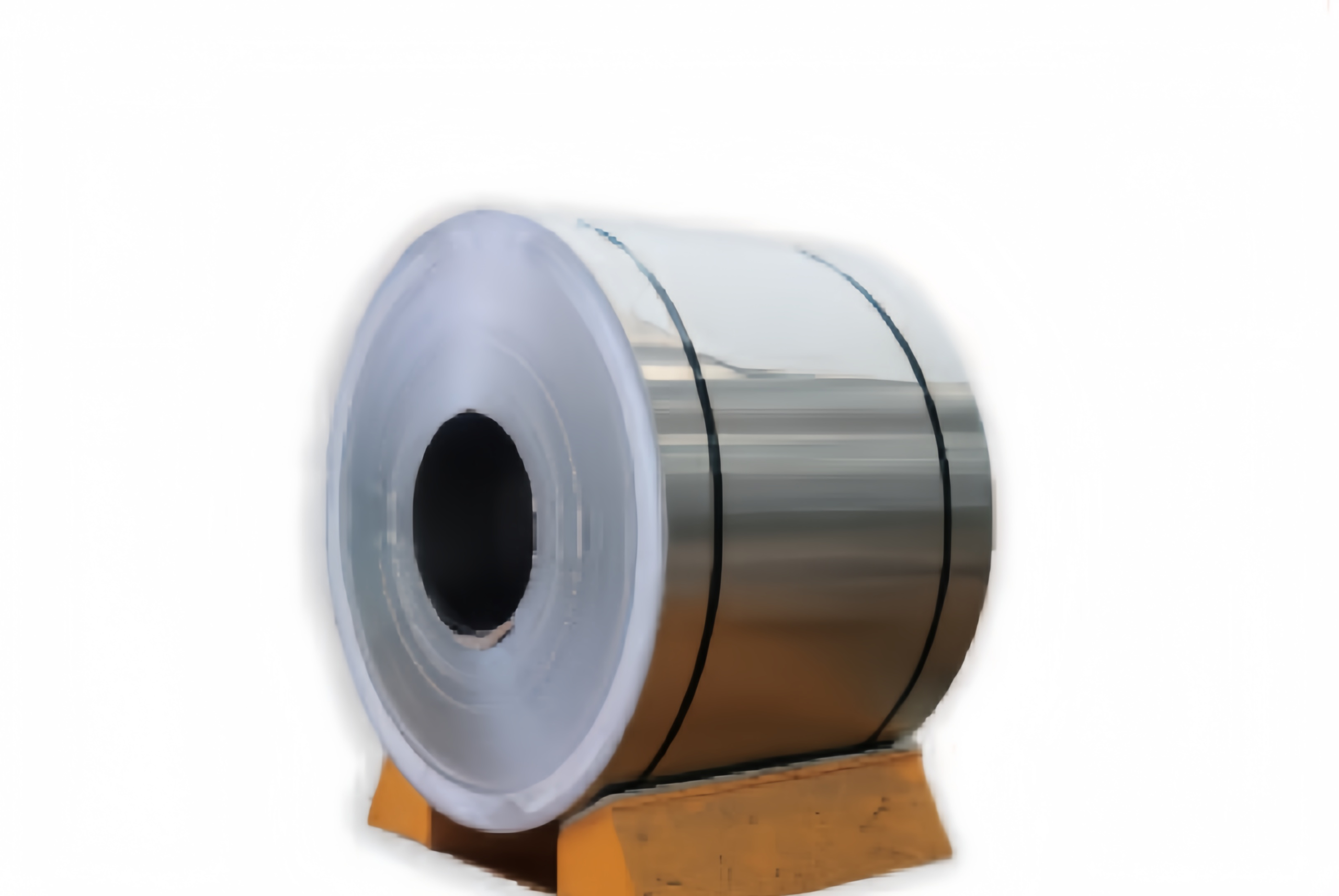

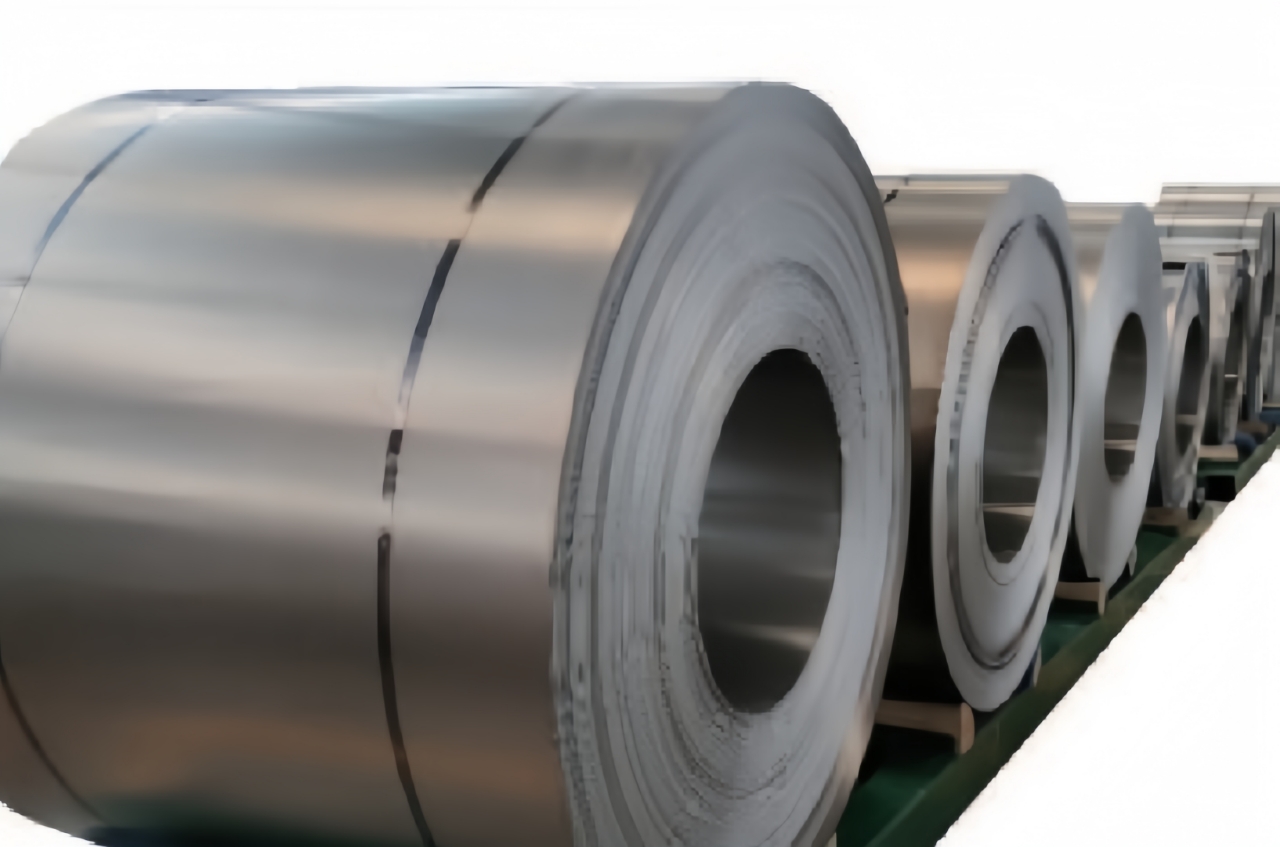

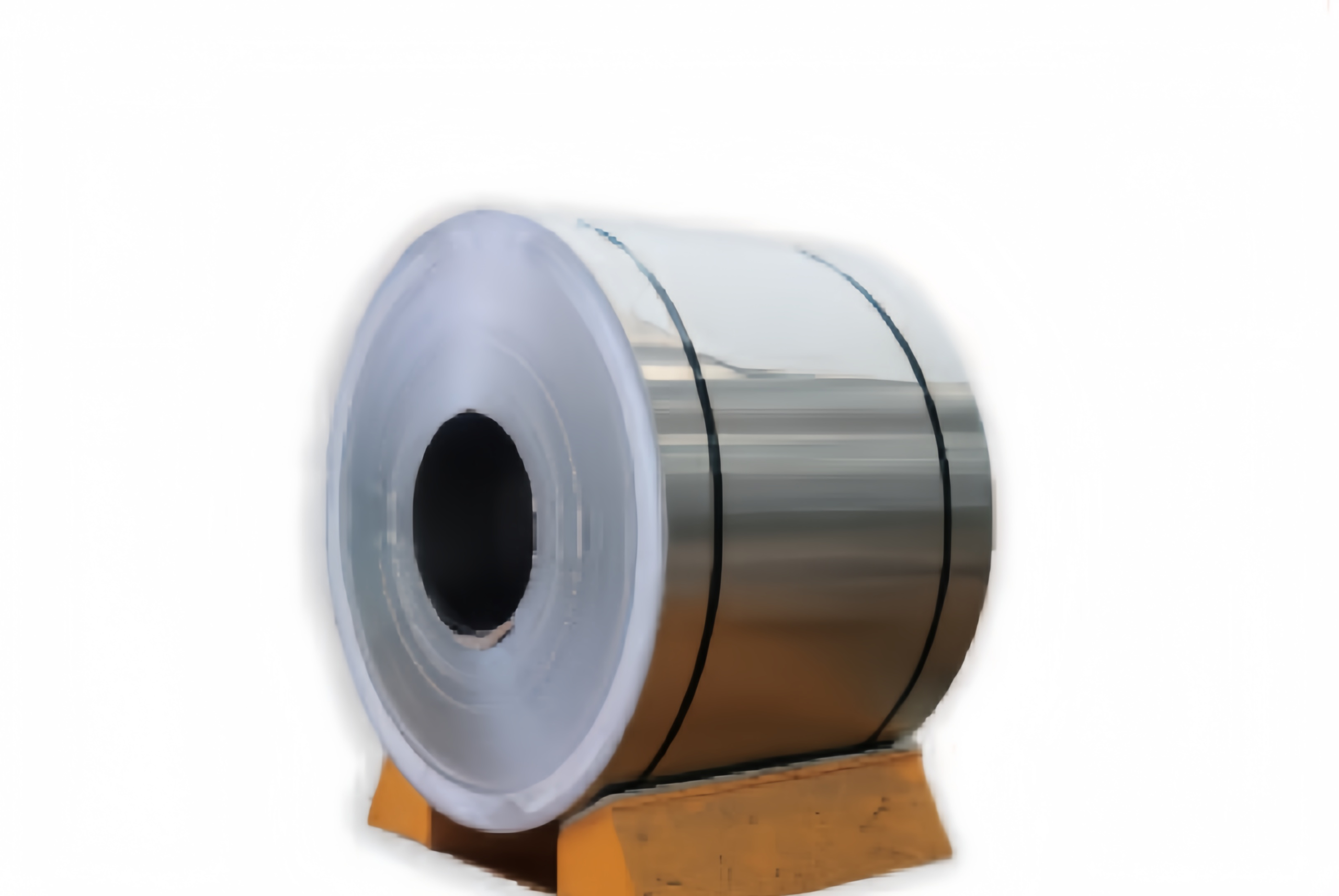

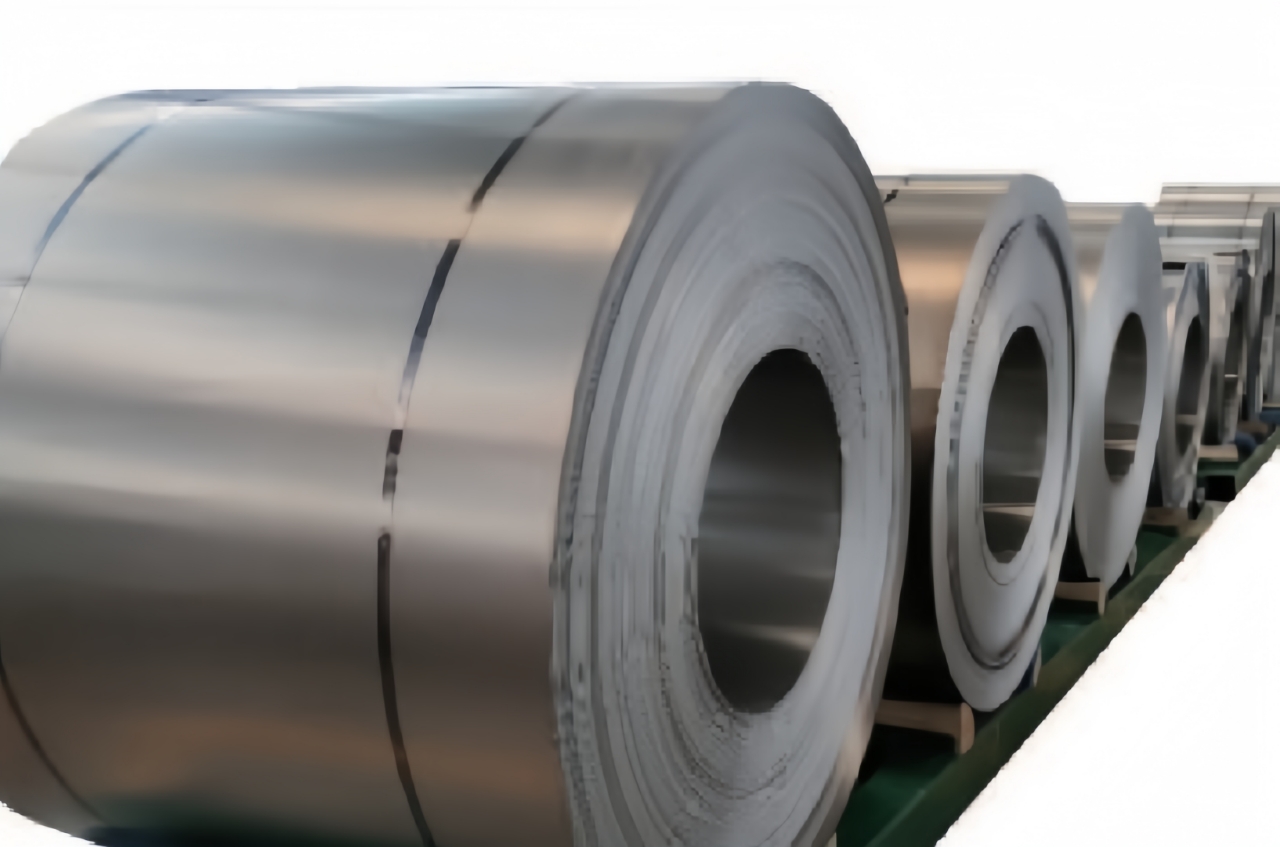

Cold &Hot Rolling Coil

TA1(Gr.1),

TA2(Gr.2), TA3(Gr.3),

TA4(Gr.4),

TA8, TA9,

TA10(Gr.12),

TC4ELI(Gr.23) etc.

Clad Coil

TA1(Gr.1),

AL:1050,1060,3003

Stainless Steel:304, 430

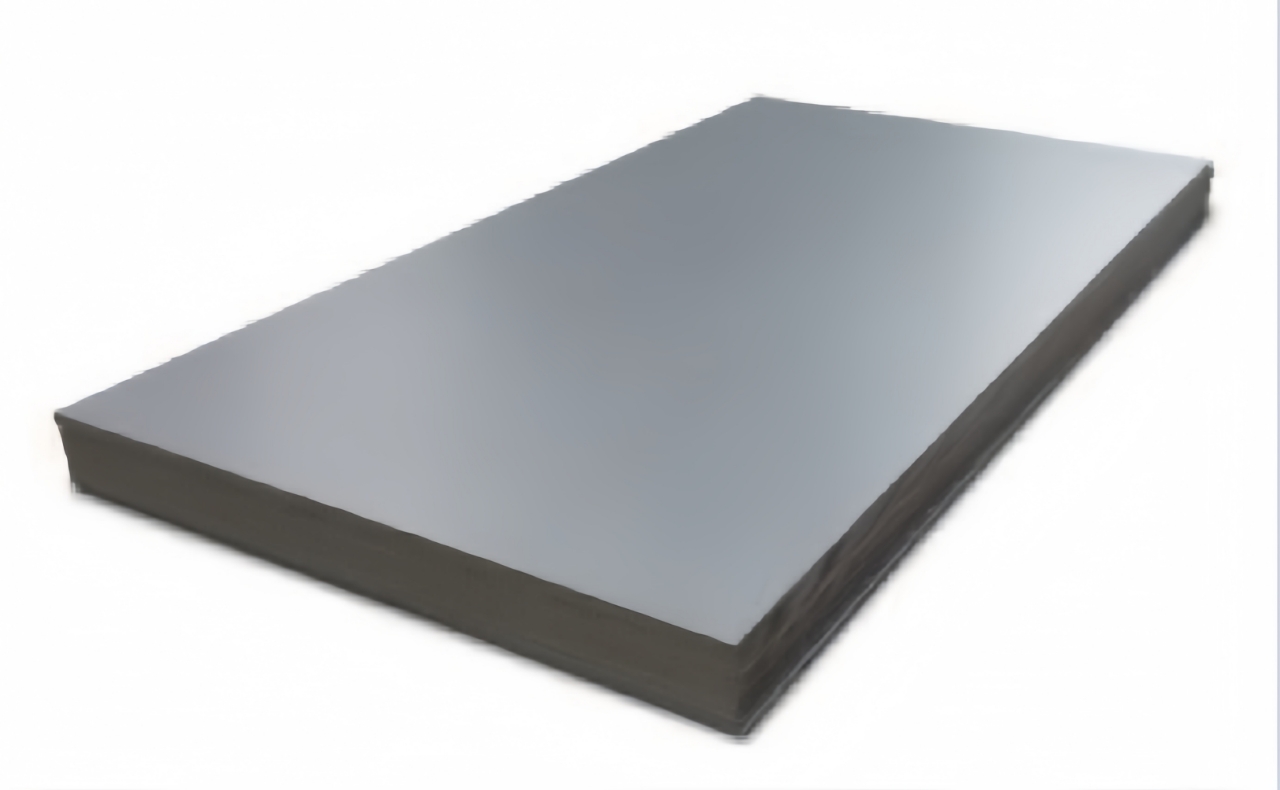

Sheet&Plate

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA4(Gr.4), TA5,TA7(Gr.6), TA8, TA9(Gr.7),TA10(Gr.12), TA15(BT20), TC1,TC2, TC4(Gr.5), TC6, TC11, TC18,TB2,TB5,TB6,T165,

T160,R60700,R60702

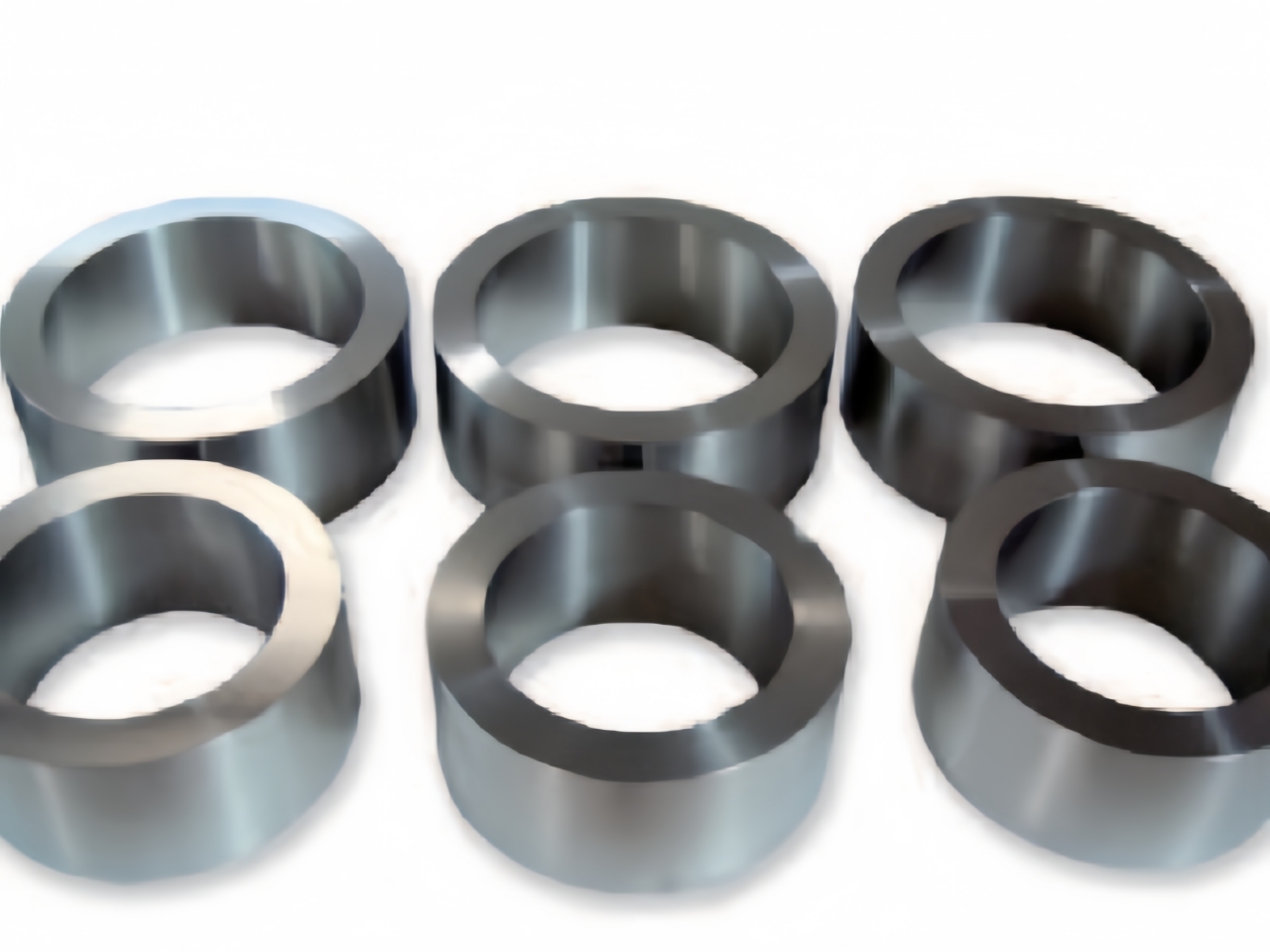

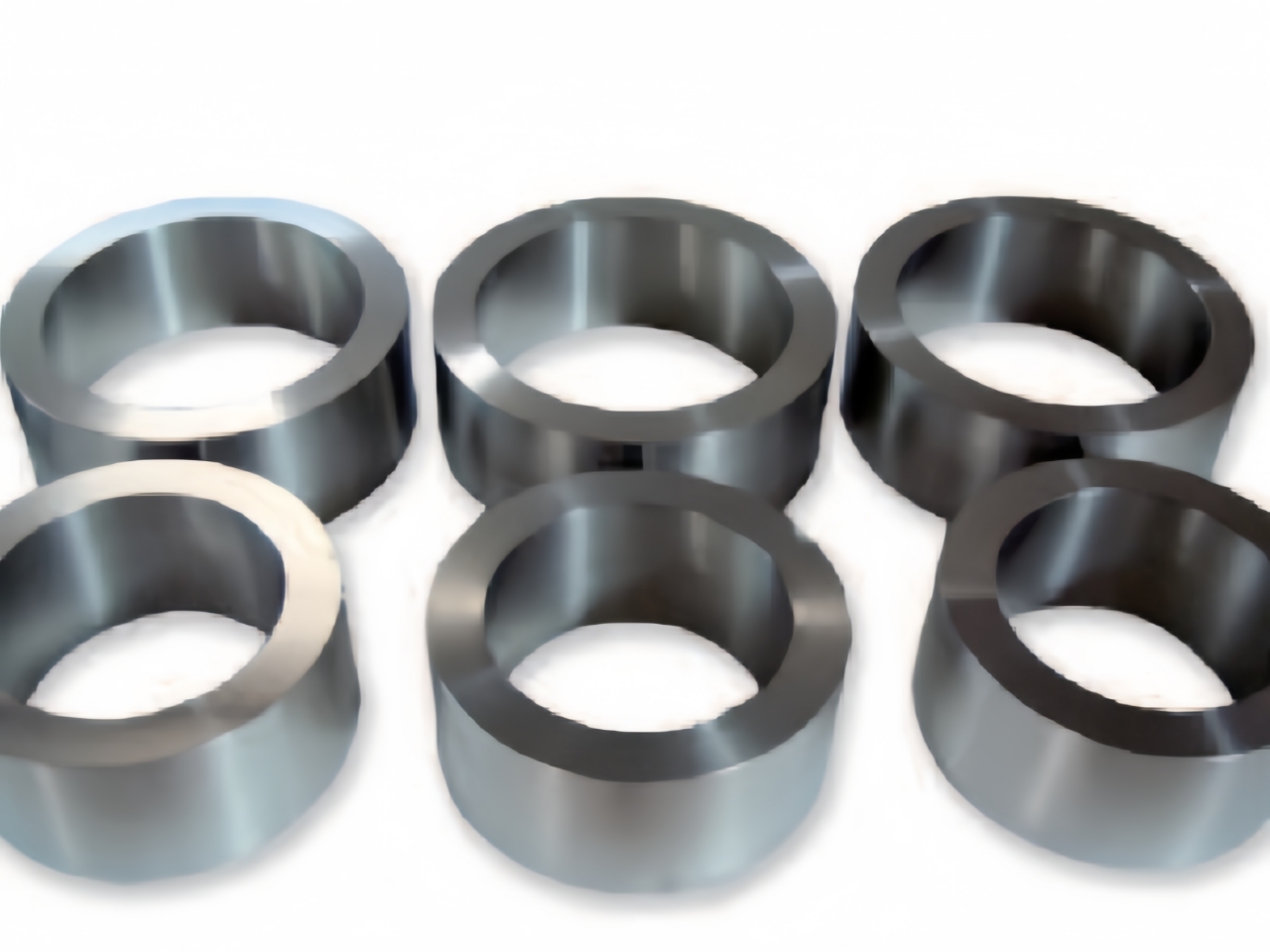

Forging

TA1(Gr.1 ), TA2(Gr.2),TA3(Gr.3),TA4(Gr.4),TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11, TC17,TC18(BT22), C.P.Ti, Gr.11,Gr.17,TI-6AI-4VELI, TC10(Ti662),TA19(Ti6242),TC19(Ti6246),TC21(-Ti62222s),TB2,TB5,TB6(Ti1023)

Billet Bar& Rod

TA1(Gr.1 ), TA2(Gr.2), TA3(Gr.3), TA4(Gr.4)TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11,TC17,TC18(BT22),C.P.Ti, Gr.11,Gr.17,Ti-6A1-4VELI, TC10(Ti662),TA19(-Ti6242),TC19(Ti6246),TC21(Ti62222s),TB2, TB5, TB6(Ti1023)

Wire

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA10(Gr.12),

TA15(BT20),TA18(Gr.9),

TC4(Gr.5),C.P.Ti, Gr.11, Gr.17,Ti-6AI-4VELI, TC16,TB3,TB8,TB13 etc.

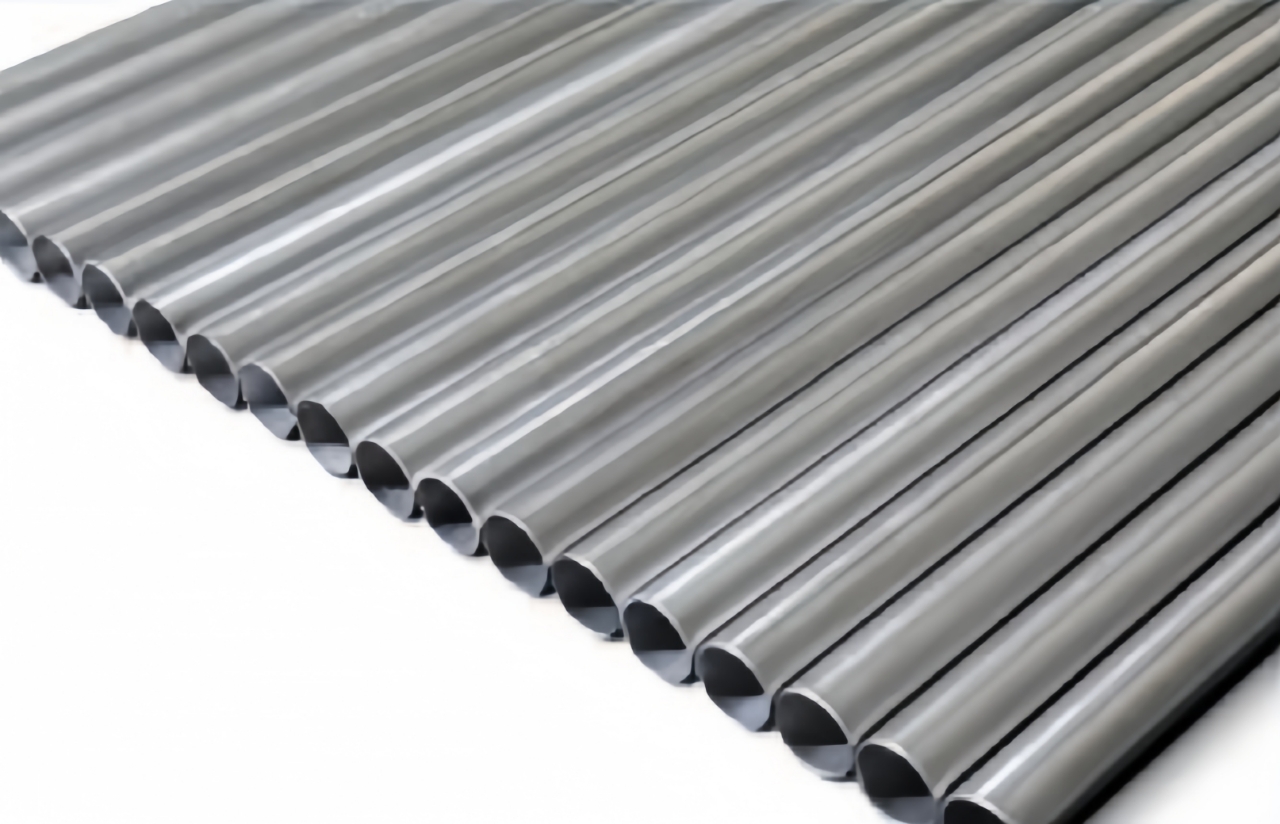

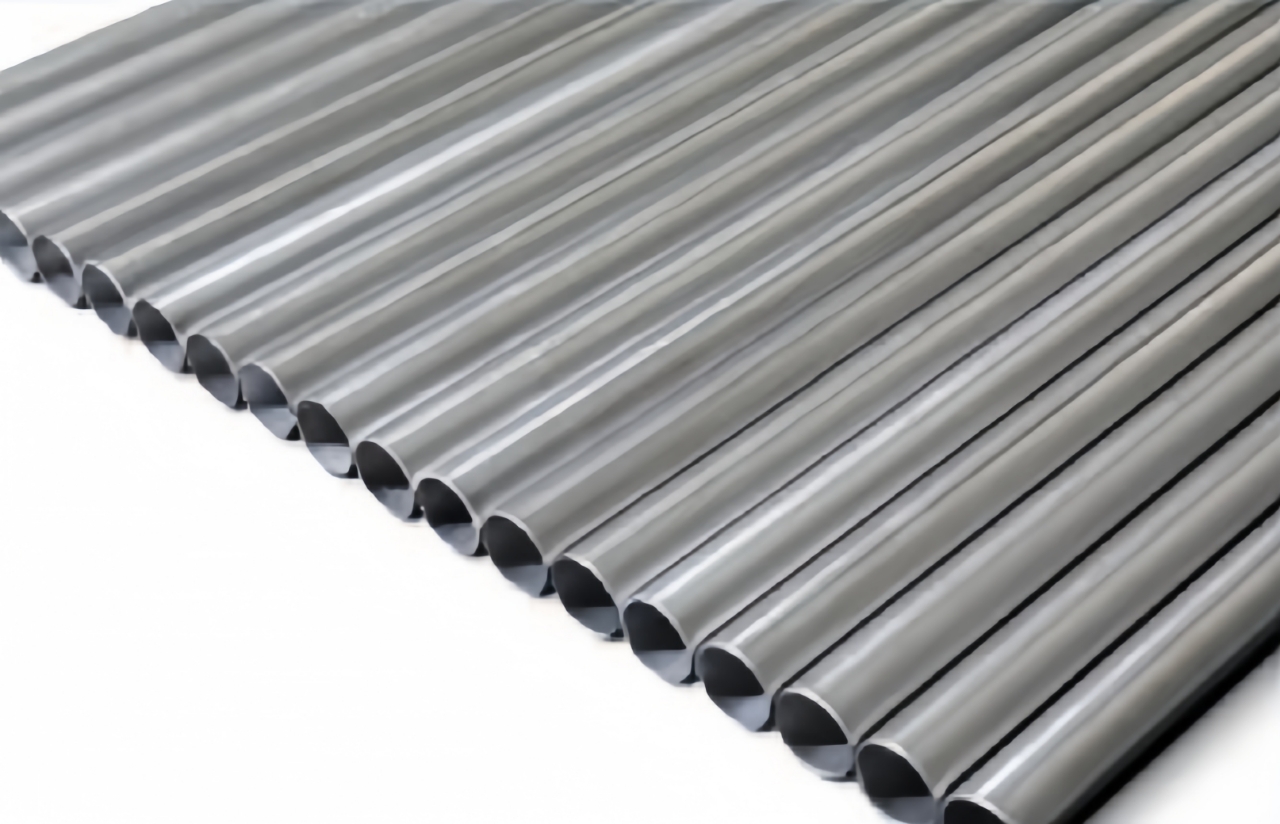

Tube Pipe

TA1(Gr.1), TA2(Gr.2), TA9(Gr.7),TA10(Gr.12), TA18(Gr.9), TC4(Gr.5),R60702 etc

Advanced Laboratory Equipment

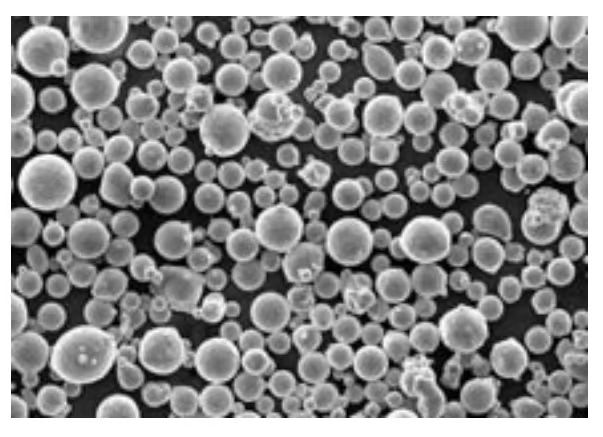

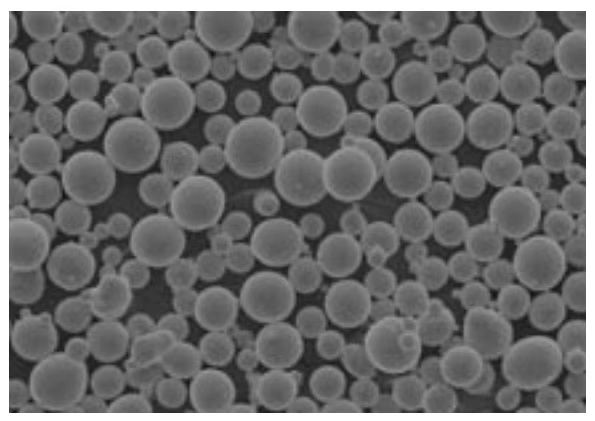

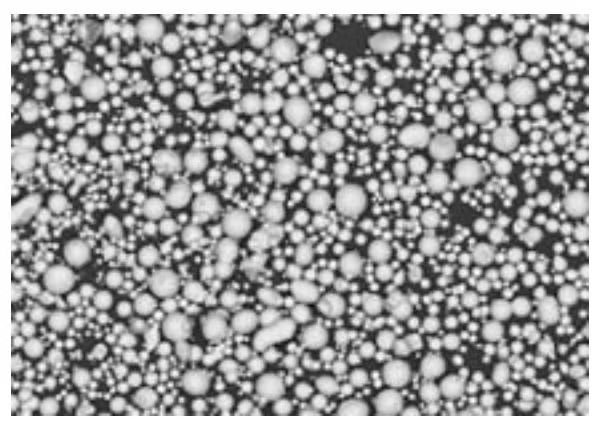

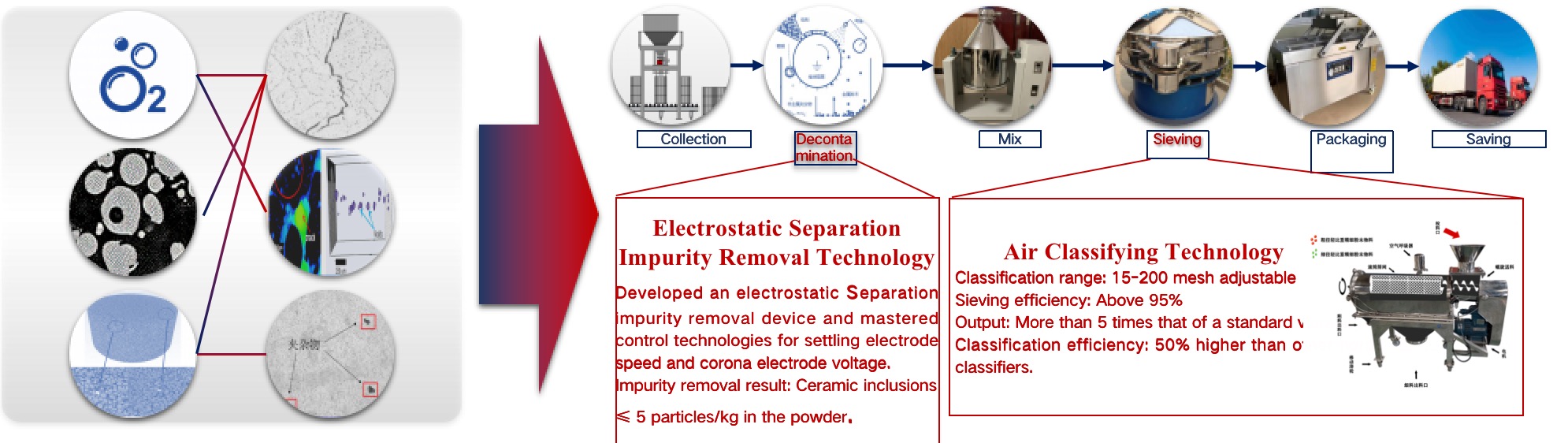

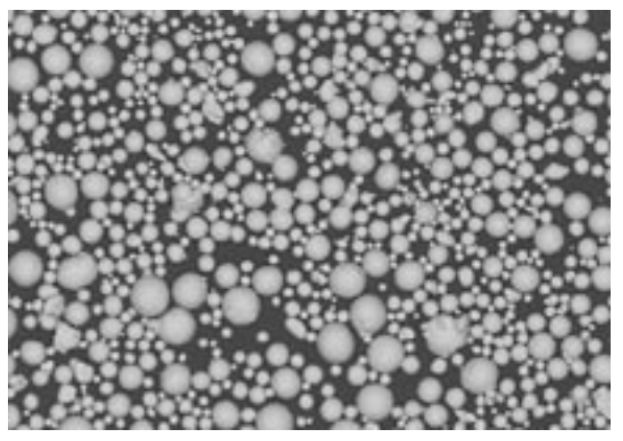

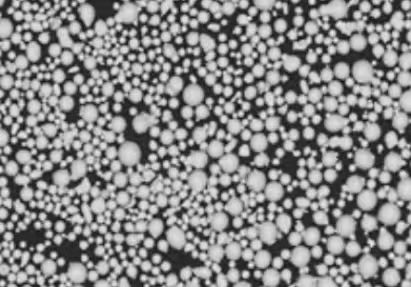

With 10years of experience in atomization powder-making technology and leveraging the country’s top laboratories, we have mastered world-leading powder production technologies. Notably, we pioneered the localization of plasma torch atomization, electrode induction melting, and gas atomization. Our titanium alloy, high-temperature alloy, and other powders are now industrialized and applied across various industries.

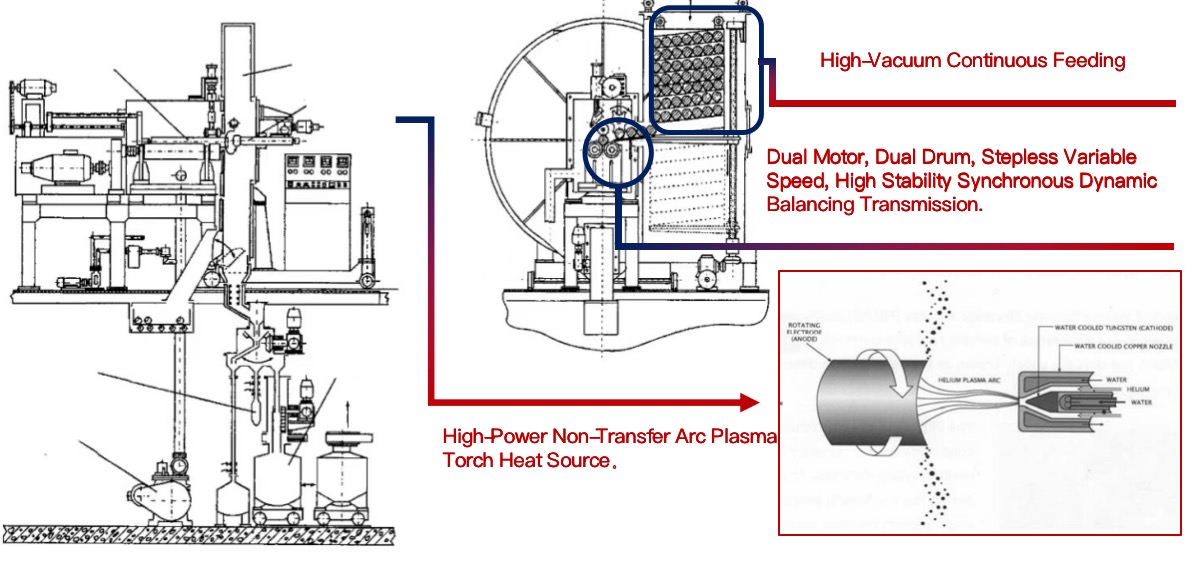

Ultra-High-Speed Rotating Electrode Atomization Powdering Technology

A unified particle size prediction technology for PREP powders has been developed. The integration of the hopper and atomization chamber enhances motor speed and dynamic balance at ultra-high rotational speeds, ensuring stable performance for metal billets.

Fine powder recovery is doubled, costs are reduced by over 50%, and the powder size is controllable for customizable production.

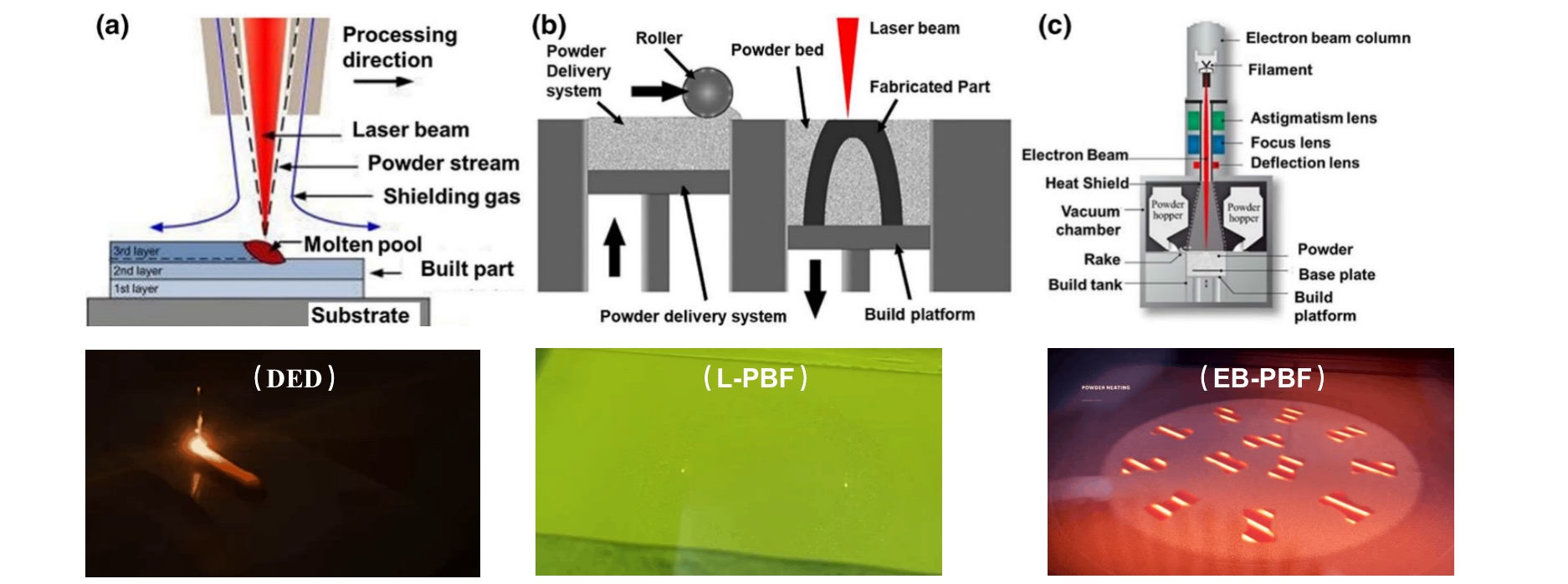

Maturation of Additive Manufacturing, Coating, and Repair Technologies

OEM and ODM are accepted

Cold &Hot Rolling Coil

TA1(Gr.1),

TA2(Gr.2), TA3(Gr.3),

TA4(Gr.4),

TA8, TA9,

TA10(Gr.12),

TC4ELI(Gr.23) etc.

Clad Coil

TA1(Gr.1),

AL:1050,1060,3003

Stainless Steel:304, 430

Sheet&Plate

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA4(Gr.4), TA5,TA7(Gr.6), TA8, TA9(Gr.7),TA10(Gr.12), TA15(BT20), TC1,TC2, TC4(Gr.5), TC6, TC11, TC18,TB2,TB5,TB6,T165,

T160,R60700,R60702

Forging

TA1(Gr.1 ), TA2(Gr.2),TA3(Gr.3),TA4(Gr.4),TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11, TC17,TC18(BT22), C.P.Ti, Gr.11,Gr.17,TI-6AI-4VELI, TC10(Ti662),TA19(Ti6242),TC19(Ti6246),TC21(-Ti62222s),TB2,TB5,TB6(Ti1023)

Billet Bar& Rod

TA1(Gr.1 ), TA2(Gr.2), TA3(Gr.3), TA4(Gr.4)TA5, TA7(Gr.6), TA8, TA9, TA10(Gr.12),TA15(BT20), TC1, TC2, TC4(Gr.5), TC6,TC11,TC17,TC18(BT22),C.P.Ti, Gr.11,Gr.17,Ti-6A1-4VELI, TC10(Ti662),TA19(-Ti6242),TC19(Ti6246),TC21(Ti62222s),TB2, TB5, TB6(Ti1023)

Wire

TA1(Gr.1), TA2(Gr.2), TA3(Gr.3),TA10(Gr.12),

TA15(BT20),TA18(Gr.9),

TC4(Gr.5),C.P.Ti, Gr.11, Gr.17,Ti-6AI-4VELI, TC16,TB3,TB8,TB13 etc.

Tube Pipe

TA1(Gr.1), TA2(Gr.2), TA9(Gr.7),TA10(Gr.12), TA18(Gr.9), TC4(Gr.5),R60702 etc

FAQs

Can you produce customized cables based on our requirements?

What types of metal powders do you offer?

We offer a wide range of metal powders including titanium, titanium alloys, and other high-performance metals. Our powders are used in various industries such as aerospace, automotive, and medical applications.

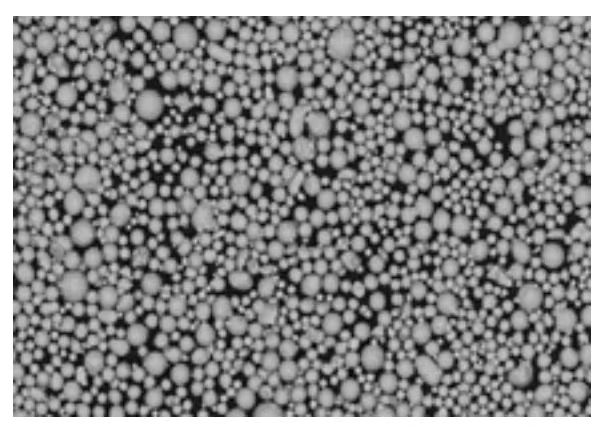

What is the particle size of your metal powders?

Our metal powders come in various particle sizes depending on your specific needs. Typical ranges include fine powders with particle sizes from 10 microns to 100 microns. We can also offer custom particle size distribution based on client requirements.

What is the purity level of your metal powders?

Our metal powders are of high purity, typically ranging from 99% to 99.99% depending on the material. We ensure strict quality control to meet industry standards.

Can you customize metal powders?

Yes, we offer customization of metal powders, including specific purity, particle size distribution, and packaging based on your unique requirements. Please contact our sales team for more details on custom orders.

Do you offer metal powder for additive manufacturing (3D printing)?

Yes, we provide metal powders suitable for additive manufacturing applications, including titanium, titanium alloys, and other materials compatible with 3D printing processes.

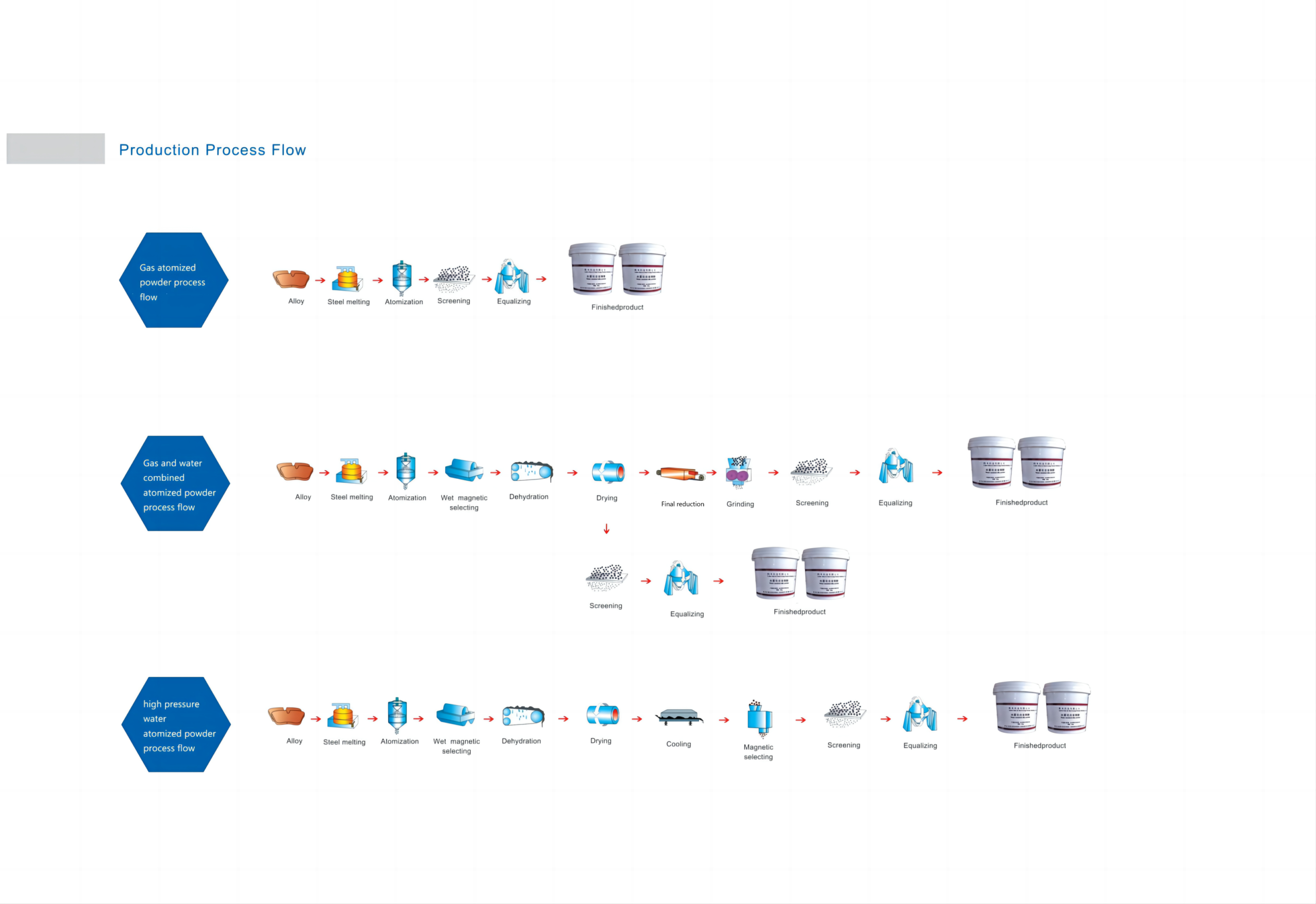

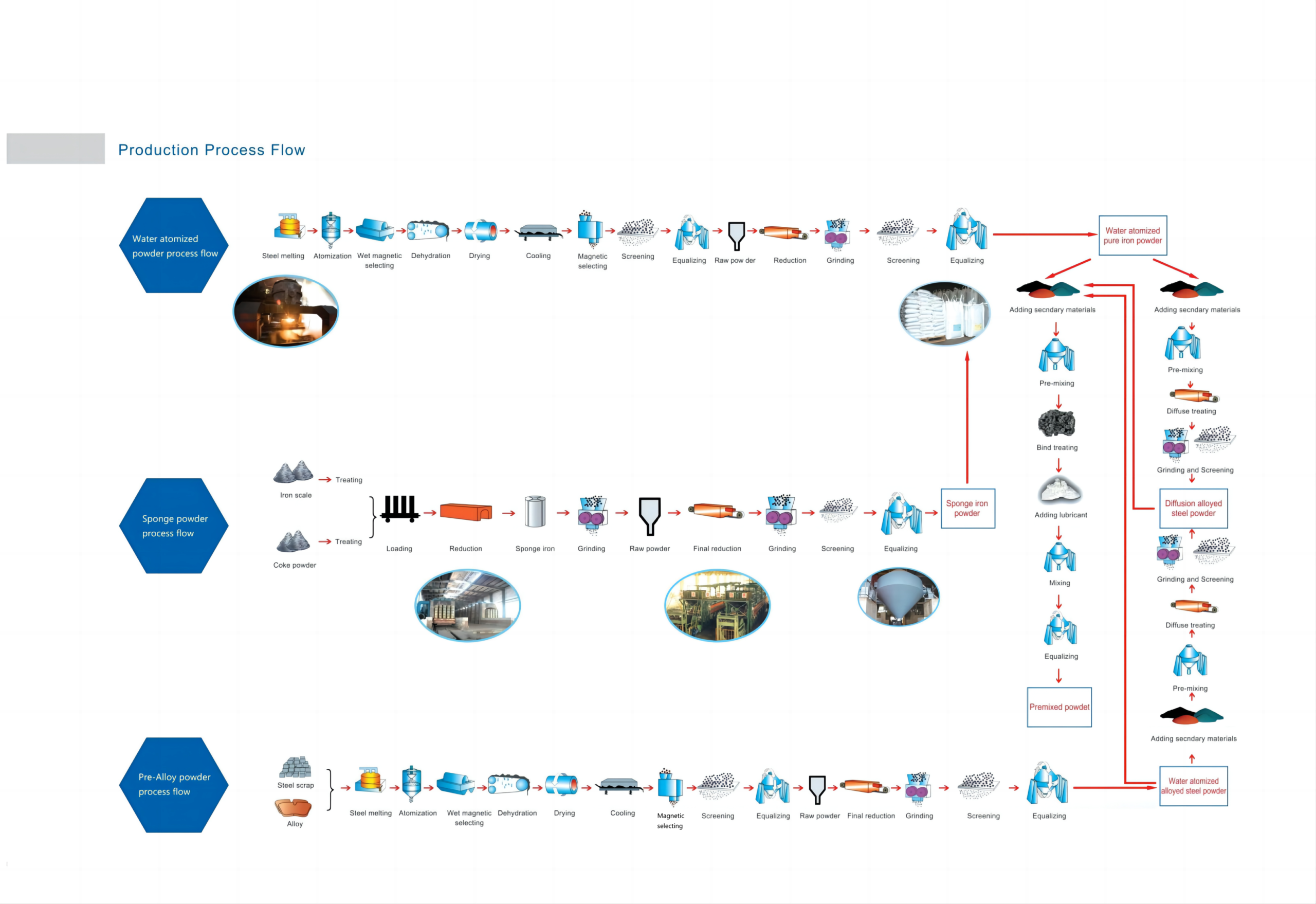

How are your metal powders produced?

Our metal powders are produced using advanced techniques such as gas atomization and atomized powder processes, ensuring consistent quality and performance.

What is the typical application of your metal powders?

Our metal powders are commonly used in industries like aerospace, automotive, medical implants, and 3D printing. They are used for manufacturing parts through processes such as powder metallurgy, additive manufacturing, and coating applications.

How do I place an order for metal powders?

To place an order or request a quote, please contact our sales team via email at [email protected] or through our website’s contact form. We will assist you with your order details, customization options, and shipping requirements.

What is the lead time for custom orders?

The lead time for custom metal powder orders depends on the specifications and quantity. Typically, it ranges from 2 to 6 weeks. Please reach out to us for more accurate timelines based on your needs.

How do you ensure the quality of your metal powders?

We conduct rigorous testing at every stage of production, including particle size analysis, purity testing, and flowability tests. Our quality assurance process ensures that our metal powders meet the highest industry standards.

Contact MetalChief

24/7 Global Support

Address:Room 701, Fengtin Building, Hefeng Creative Square, No. 375 Jiangdong North Road, Building 006 (7-1), Yinzhou District, Ningbo City, Zhejiang Province, China

Call Us: + 86 18668881072

Email Us:[email protected]