Your Partner for Advanced Metal Manufacturing and Materials

OEM and ODM are accepted,

Composition and particle size can be customized.

Titanium and Titanium Alloy Powders

TA1 , TC4 , TA15,TA15 ,

TiAl4822, Ti2AlNb, NiTi50, TA17, TA18, TC11, TC19, TC31, etc.

High-Temperature Alloy Powders

GH3230 ,GH3536,GH3625,GH4099,GH4169,GH5188,M247、K438、M509、EP648、In939

Advanced Laboratory Equipment

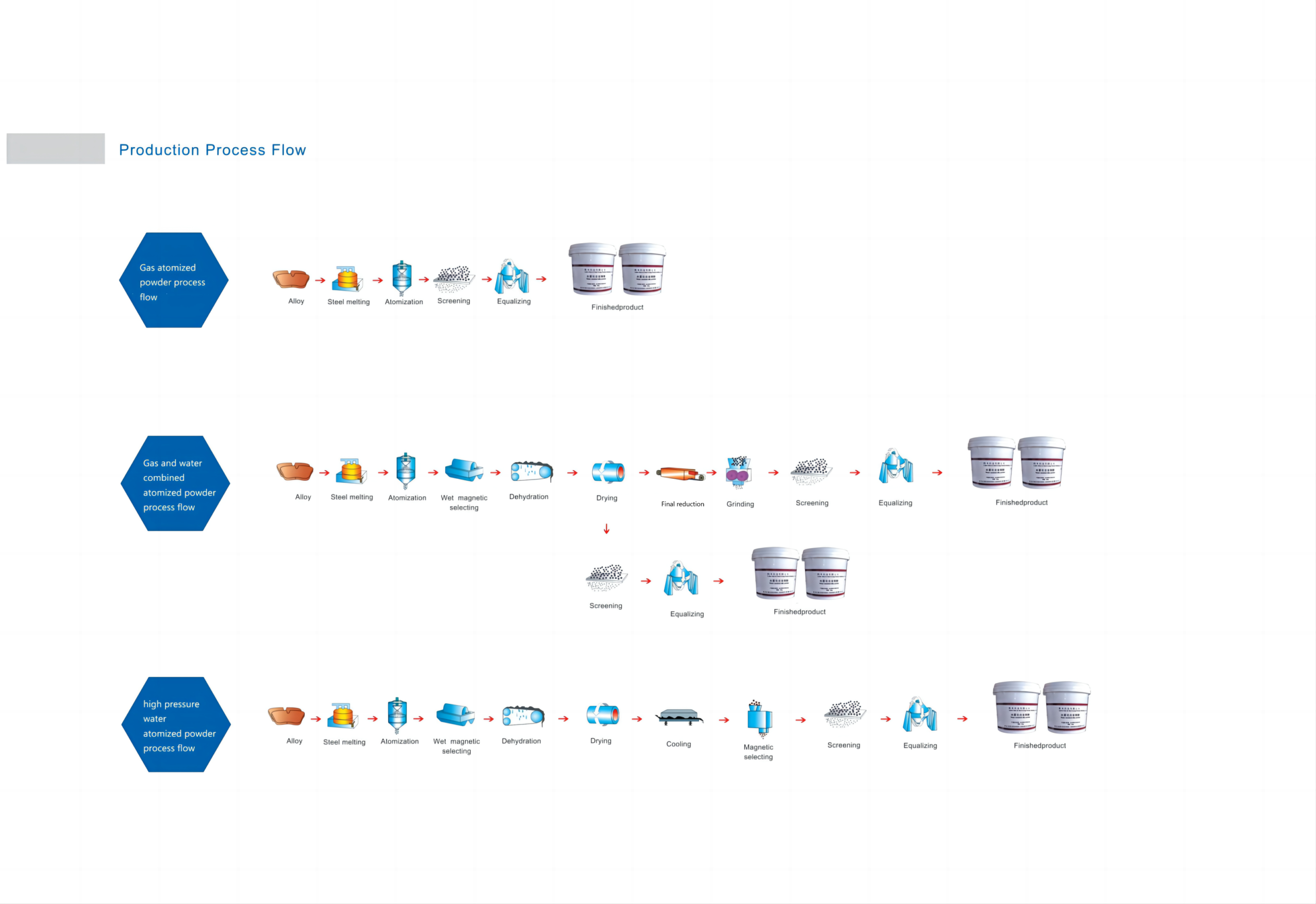

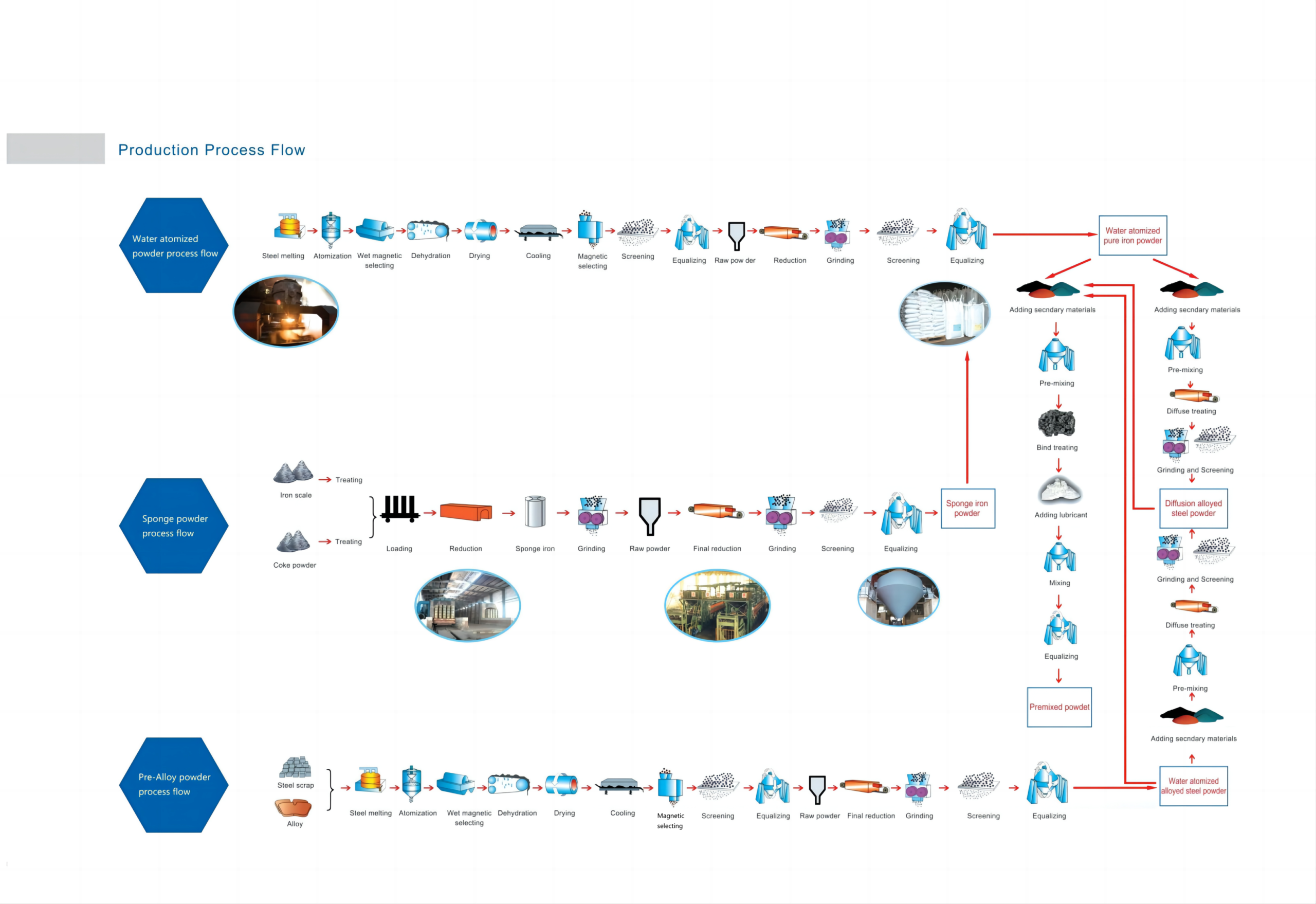

With 10years of experience in atomization powder-making technology and leveraging the country’s top laboratories, we have mastered world-leading powder production technologies. Notably, we pioneered the localization of plasma torch atomization, electrode induction melting, and gas atomization. Our titanium alloy, high-temperature alloy, and other powders are now industrialized and applied across various industries.

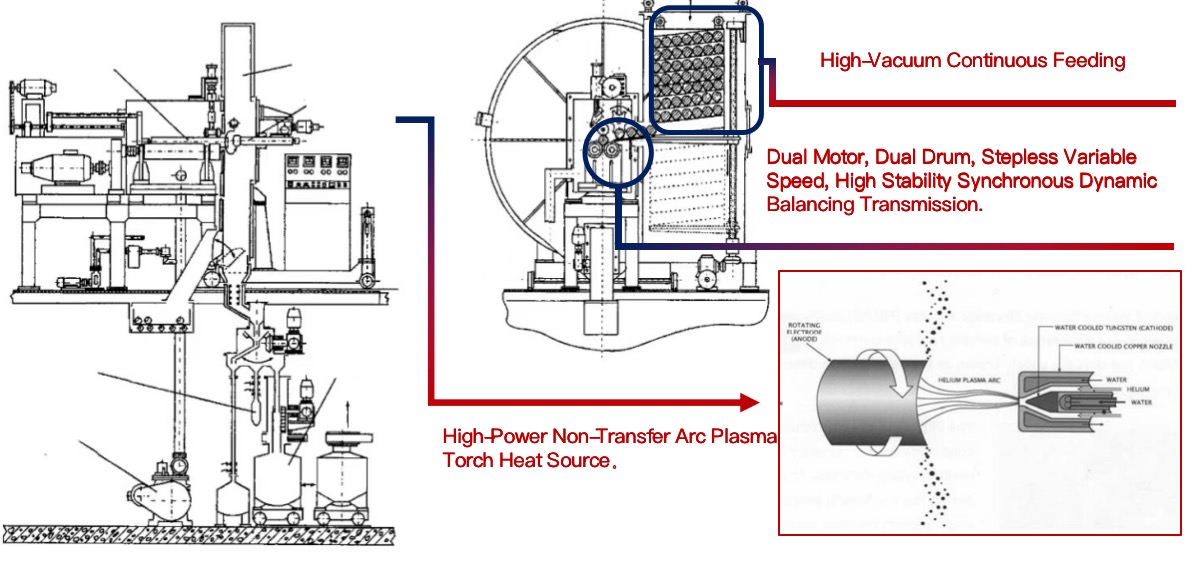

Ultra-High-Speed Rotating Electrode Atomization Powdering Technology

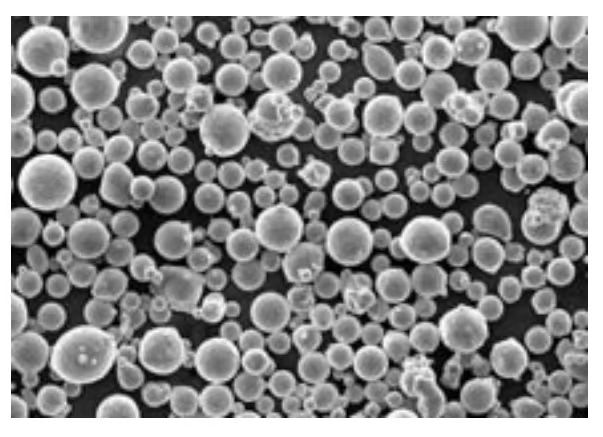

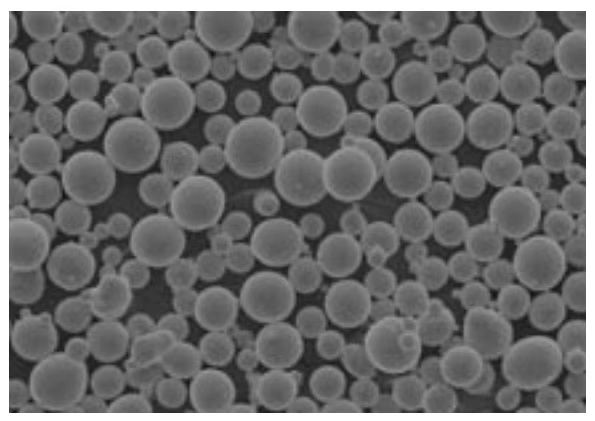

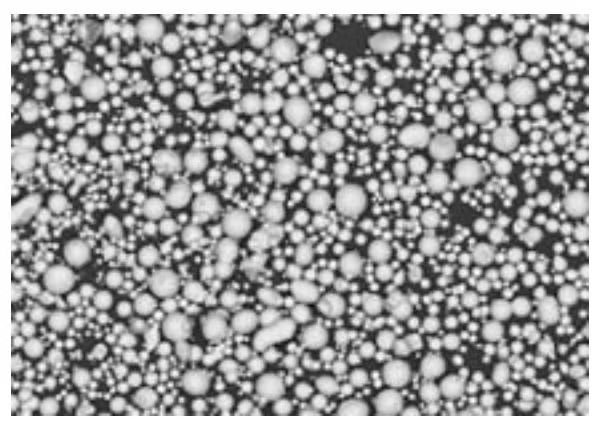

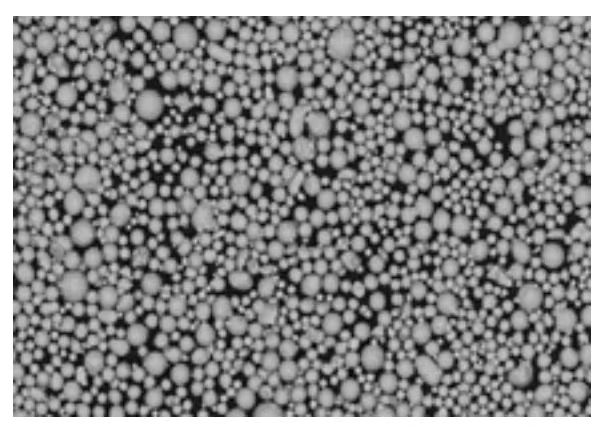

A unified particle size prediction technology for PREP powders has been developed. The integration of the hopper and atomization chamber enhances motor speed and dynamic balance at ultra-high rotational speeds, ensuring stable performance for metal billets.

Fine powder recovery is doubled, costs are reduced by over 50%, and the powder size is controllable for customizable production.

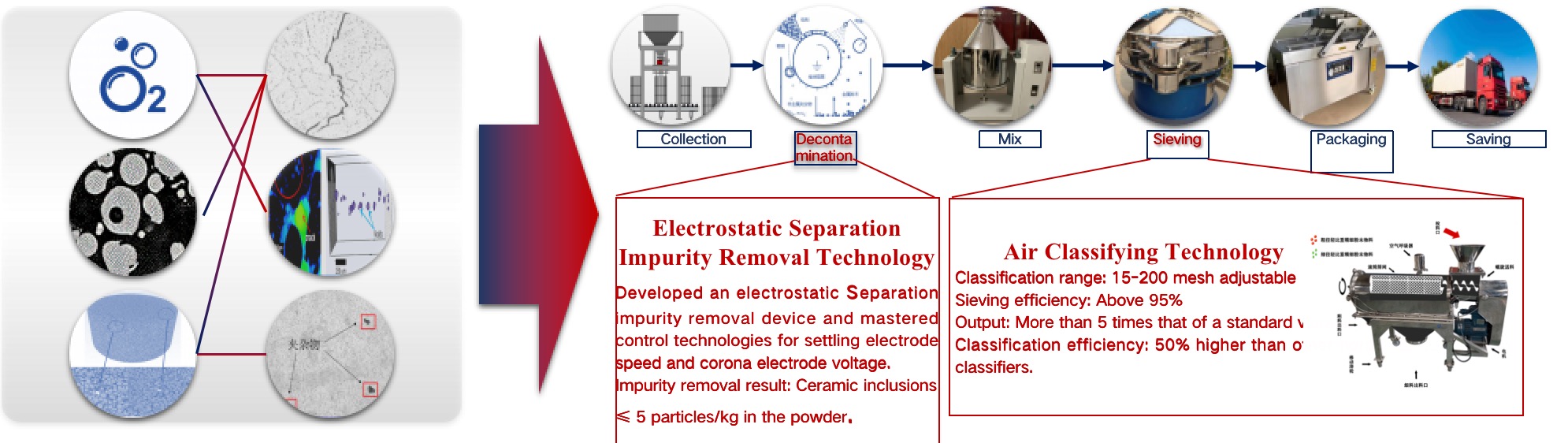

Tri-Mode Powder Purification Technology

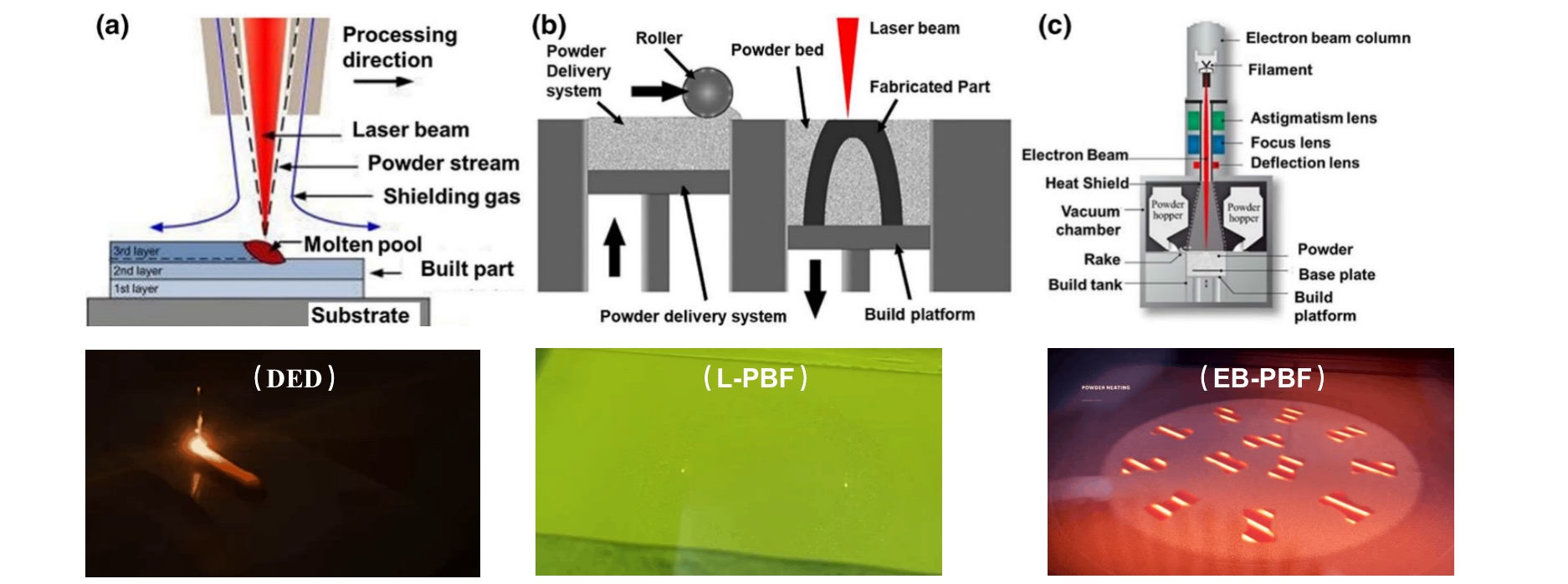

Maturation of Additive Manufacturing, Coating, and Repair Technologies

About Us

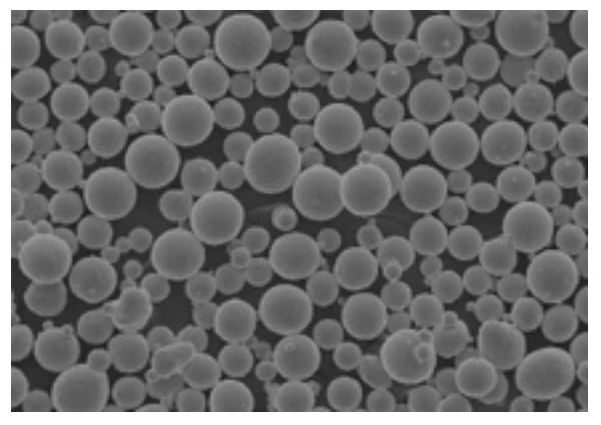

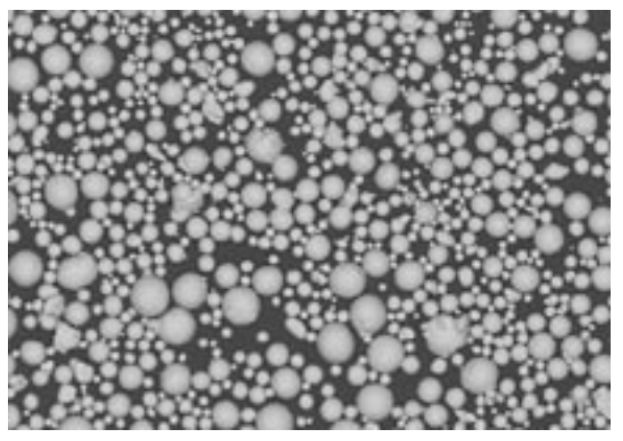

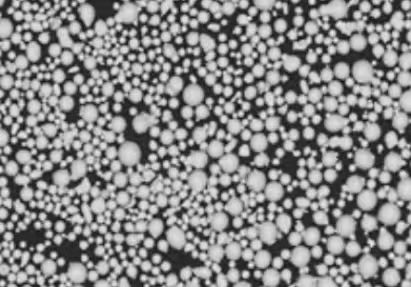

We have developed advanced Plasma Rotating Electrode Powder Production (PREP) equipment, producing ultrafine, high-purity spherical metal powders with excellent flowability, no hollow particles, high sphericity, and controllable particle size. These powders meet the requirements for 3D printing, coating, and powder metallurgy processes, and are suitable for both military and civilian applications, with a promising market outlook.

Our core team, from the Powder Metallurgy National Key Laboratory at Central South University, is highly skilled. We focus on high-end alloy powder raw materials, powder metallurgy products, and small-scale PREP powder production equipment.

We provide competitive, safe, and reliable products and services across aerospace, medical devices, and high-end equipment sectors. By collaborating with industry partners, we aim to create value, drive innovation, and promote growth in advanced manufacturing.

We prioritize customer needs through innovation and invest in research to advance our industry. Externally, we create value for customers; internally, we reward hard work and ensure fairness. We foster a win-win ecosystem with partners and comply with local laws, contributing to job creation and green manufacturing.

Empowering Your Choices with Quality and Precision.

Choosing the right metal powder solutions can be challenging, but with METALCHIEF, you make confident decisions. With our expertise, precision manufacturing, and strong supply chain, we deliver unmatched quality and value every time.